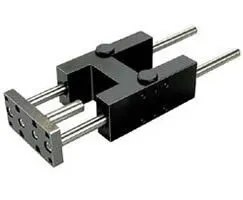

Norgren QA/8100/51/500 Guide Block Cylinder - 100 mm Bore

Part Number: QA/8100/51/500

Quick Summary

QA/8100/51/500 guide block cylinder delivers precise linear actuation for automation and control systems. Engineers often struggle with misalignment, wear, and maintenance in long-stroke cylinders, reducing uptime and increasing maintenance costs. CE marking and IP-rated protections are commonly leveraged in this family to meet safety and environmental requirements, with ISO 9001 quality management underpinning consistent manufacturing. This actuator combines robust plain bearing guidance with a long-stroke profile to deliver reliable motion in demanding lines. By optimizing compatibility and using standard mounting patterns, customers gain easier integration, lower retrofit risk, and measurable reductions in lifecycle costs while maintaining high performance in automated assembly and material-handling applications.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm cylinder bore and 500 mm stroke provide extended reach and predictable stroke length, enabling higher throughput in automated assembly lines. Business Impact: Increased part-handling capability and faster cycle times, reducing overall cycle time and boosting line productivity in demanding workflows. Application: Ideal for pick-and-place and transfer tasks on conveyor systems where reach and repeatability matter. Feature: Plain bearing guide block design minimizes friction and wear, delivering smoother motion and longer service life. Business Impact: Lower maintenance intervals and reduced replacement parts cost, improving uptime and total cost of ownership. Application: Benefit in high-cycle environments such as packaging or automotive assembly where consistent travel is critical. Feature: Compact integration with standard mounting patterns and compatibility with Norgren accessory ecosystem. Business Impact: Faster design-in and retrofit, shorter installation time, and fewer compatibility surprises in existing lines. Application: Retrofit projects and new builds across factory floors using common 100 mm bore actuators. Feature: CAD resources and installation guidance are readily available, accelerating engineering and commissioning. Business Impact: Speeds up digital twin modeling, reduces design errors, and shortens test phases. Application: Design engineer onboarding, shop-floor commissioning, and maintenance planning. Feature: Brand reliability and build quality, with options for regional certifications and environmental protection. Business Impact: Consistent performance under harsh conditions, compliance assurance, and risk reduction in regulated sectors. Application: Industrial automation, machinery in heavy-duty environments, and process lines where reliability is essential.

Get a Quick Quote for a Norgren QA/8100/51/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/500?

Enquire Now

FAQs

QA/8100/51/500 uses standard mounting interfaces common to Norgren 100 mm bore actuators, enabling quick retrofit into existing frames without major rework. The product page provides CAD models and installation guidance to streamline design-in. Engineers should verify the exact mounting pattern in the installation guide to confirm compatibility with legacy 51-series components and available Norgren accessories.

Expect strong reach with consistent stroke length, enabling efficient part transfer and controlled positioning. The 100 mm bore supports adequate force for typical pick-and-place tasks, while the 500 mm stroke offers extended travel for longer cycles. In high-cycle environments, the plain bearing guide reduces friction wear, improving cycle reliability and reducing maintenance downtime.

Yes. The product page includes an Installation Guide (PDF) and CAD download, designed to speed up commissioning and minimize setup errors. These resources cover mounting options, tolerances, and alignment procedures, helping technicians achieve accurate alignment, proper air connections, and safe, efficient operation with minimal line stops.

Regulatory compliance typically depends on regional requirements and the chosen configuration. Norgren actuators commonly include CE marking and IP-rated variants to address safety and environmental exposure. For applications in hazardous environments, verify the exact IP rating and any SIL considerations in the regional specification and the installation guides to ensure compliance and safe operation.

The plain bearing guide reduces friction and wear, extending service life and lowering maintenance costs in high-cycle use. With a longer maintenance interval, downtime decreases, boosting overall equipment effectiveness. ROI improves further when combined with quick design-in via CAD assets and familiar mounting patterns, enabling faster project completion and predictable performance over the asset’s life.