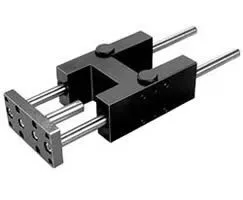

Norgren QA/8100/61/160 Guide block - 100 mm bore

Part Number: QA/8100/61/160

Quick Summary

Norgren QA/8100/61/160 guide block delivers precise linear motion for pick-and-place and automation tasks. Engineers often struggle with misalignment, vibration, and downtime in compact automation cells. This family is designed with CE compliance in mind and robust integrity via protective ratings, aligning with standard industry requirements. With a 100 mm bore and 160 mm stroke, the unit supports reliable actuation in tight spaces, reducing cycle time and downtime. Designed for industrial applications, this product strengthens uptime in packaging, assembly, and general automation environments. Secondary keywords like pneumatic actuator, IMI Norgren, and guide block appear naturally in specifications, aiding digital discovery for buyers. Procurement teams benefit from predictable performance, standardized mounting, and long service life, translating to lower lifecycle cost.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8100/61/160 offers a 100 mm bore and 160 mm stroke, delivering substantial actuation force within a compact footprint, enabling faster cycle times in automated pick-and-place and packaging lines. This directly translates to higher throughput and reduced downtime in the production cell. Feature → Business Impact → Application: The guide block roller bearing style provides low friction, high stiffness, and precise motion, which reduces wear, improves repeatability, and extends service life in robotics and machine-tending tasks. This supports long-term cost savings and consistent quality in electronics assembly and automotive suppliers. Feature → Business Impact → Application: Standard mounting compatibility and available CAD assets simplify integration, shorten commissioning, and reduce engineering risk when retrofitting existing lines or expanding automation capacity across packaging and processing lines. Feature → Business Impact → Application: CE compliance considerations and robust construction help meet regulatory expectations in Europe and comparable markets, while delivering reliable operation in harsh production environments. Feature → Business Impact → Application: The availability of installation guides and documentation accelerates onboarding for maintenance teams, ensuring predictable lubrication intervals and easier spare-part planning for pneumatic actuators in high-mix, low-volume production.

Get a Quick Quote for a Norgren QA/8100/61/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/61/160?

Enquire Now

FAQs

To install, verify compatibility with your existing mounting pattern and refer to the Installation Guide (PDF) for torque values, bore alignment, and fastener sequences. Use the CAD resources to model the unit in your assembly, ensuring proper clearance and support. Confirm the stroke and end-of-line positions match your cycle requirements to avoid binding.

The actuator features a 100 mm bore and a 160 mm stroke, delivering strong thrust within a compact envelope. A longer stroke increases reach per cycle, reducing the number of actuators needed for extended travel, while the 100 mm bore provides sufficient force for typical pick-and-place and push/pull tasks, improving overall cycle efficiency.

This guide block design is intended for industrial automation, where robustness and reliability matter. Compliance considerations, such as CE marking, are addressed in regional configurations. Always verify the specific regional certifications for your deployment and consult the documentation for maintenance and protective-rating details relevant to your environment.

The QA/8100/61/160 line is built to meet common industry standards and is offered with CE considerations in mind for European markets. Certification availability may vary by region and configuration; check the datasheet and region-specific documentation to confirm exact compliance, including any SIL or IP-related requirements applicable to your regulatory context.

Expect improved uptime due to higher rigidity and reduced misalignment, which lowers scrap and rework in automation tasks. For maintenance, follow the lubrication and service intervals outlined in the Installation Guide and CAD resources; using genuine Norgren spares and seals helps maintain performance and extend the life of the pneumatic cylinder in continuous operation.