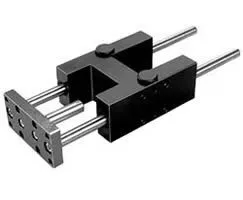

Norgren QA/8100/61/200 Guide Block Cylinder - 100 mm Bore

Part Number: QA/8100/61/200

Quick Summary

The Norgren QA/8100/61/200 guide block roller bearing cylinder delivers precise linear motion for automated assembly and handling across modern production lines. Engineers frequently confront misalignment, increased friction, and wear with long-stroke actuators, which degrade position accuracy and raise maintenance costs. Key considerations include standard CE conformity, robust lubrication, and protective roller-guide bearings that minimize ingress, jitter, and wear under demanding cycles. For project teams, faster deployment, CAD-friendly integration, and readily available installation materials translate into lower engineering time and quicker time-to-value. The combination of a 100 mm bore and a 200 mm stroke supports a wide range of automation tasks while preserving a compact footprint.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 200 mm stroke provide a compact actuator footprint with substantial travel, enabling precise, repeatable positioning in constrained spaces. Business impact: improved cycle accuracy and predictable performance reduce scrap and rework while supporting higher line throughput. Application: high-density packaging and small-assembly cells where space is at a premium. Feature: Guide block roller bearing style 61 minimizes side load and friction, delivering smoother motion and longer life. Business impact: reduced wear translates to lower maintenance frequency and longer service intervals, cutting lifecycle costs. Application: high-cycle automation, rotary-to-linear transitions, and pick-and-place tasks that demand consistent acceleration/deceleration profiles. Feature: CAD download availability and installation guidance streamline engineering and field setup. Business impact: faster onboarding for new lines and easier retrofit projects, lowering project risk. Application: retrofits in aging lines and new installation projects across automotive, food & beverage, and consumer electronics manufacturing. Feature: standard mounting compatibility with Norgren ecosystems simplifies integration. Business impact: reduced engineering hours, fewer custom fixtures, and quicker validation. Application: modular automation cells and scalable systems where uniform interfaces matter for maintenance and spares. Feature: Robust design and material selection support reliable operation in demanding environments. Business impact: higher uptime, better MTBF, and improved overall equipment effectiveness (OEE). Application: continuous operation lines in packaging, logistics, and material handling where downtime is costly.

Get a Quick Quote for a Norgren QA/8100/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/61/200?

Enquire Now

FAQs

To install, verify mounting pattern compatibility with your existing fixture, connect the 100 mm bore cylinder to the rail or guide, and follow the Installation Guide (PDF) for torque specs, air supply pressure, and lubrication recommendations. Use the CAD files to ensure correct clearance and alignment before commissioning to avoid misalignment and wear.

Key specs are a 100 mm bore and 200 mm stroke, combined with a roller bearing guide that reduces friction and side load. These features contribute to consistent acceleration, reduced dwell time between cycles, and improved repeatability across repetitive picks, transfers, and assembly motions on automated lines.

Yes, for many packaging and light-to-medium duty assembly tasks, the roller-guided design supports stable, high-velocity travel with minimized deflection. For extreme loads or very high speeds, verify load ratings and cycle requirements with the datasheet and consider additional damping or sequential actuation strategies.

Check for CE conformity where applicable and confirm any industry-specific certifications required for your region or sector. While the model is designed for industrial use, always consult the data sheet and supplier documentation to confirm IP ratings, safety certifications, and SIL considerations for your safety-critical applications.

The roller-bearing guide, 100 mm bore, and 200 mm stroke reduce wear and downtime, improving MTBF and OEE. CAD resources shorten engineering time and accelerate deployment, lowering total project costs. Over the equipment life, this translates to lower maintenance labor, fewer component replacements, and faster time-to-value for automation upgrades.