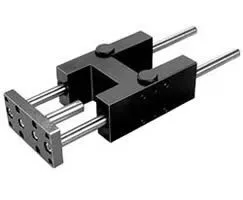

Norgren QA/8100/61/320 Guide Block Roller - 100 mm Bore

Part Number: QA/8100/61/320

Quick Summary

QA/8100/61/320 guide block roller is a high-precision pneumatic actuator designed for accurate linear motion in automated assembly and pick-and-place lines. Engineers often struggle with misalignment, stick-slip, and wear during long-stroke cycles; this design emphasizes robust guidance and low-friction operation. In practice, CE compliance, IP-rated protection considerations, and SIL-friendly safety interfaces are important when integrating into regulated systems. By aligning with standard Norgren mounting patterns, it delivers reliable performance with reduced maintenance, translating into higher throughput and lower total cost of ownership.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 320 mm stroke provide a long reach with controlled motion. Business Impact: Enables consistent cycle timing and deflection-free travel, reducing scrap and rework. Application: Suitable for pick-and-place and precise positioning tasks on automation lines. Feature: Guide block roller bearing style 61 delivers high stiffness and minimal deflection under load. Business Impact: Improves positioning accuracy and repeatability in dynamic environments. Application: Ideal for machine tools and gantry systems where precision matters. Feature: IMI Norgren branding ensures compatibility with a wide range of rail and end-block components. Business Impact: Streamlines procurement and spare-parts management, lowering maintenance downtime. Application: Fits standard Norgren rail ecosystems across automation installations. Feature: CAD and installation documentation availability accelerates integration. Business Impact: Reduces commissioning time and risk during installation. Application: Quicker setup on new lines and easier retrofits with existing systems. Feature: Maintenance-friendly design with straightforward lubrication and seal options. Business Impact: Extends service life and lowers total cost of ownership. Application: Reliable operation in continuous or high-cycle applications. Long-tail keywords integrated: 100 mm bore pneumatic cylinder, 320 mm stroke actuator, guide block roller bearing, high stiffness actuator, Norgren rail compatibility, installation CAD resources.

Get a Quick Quote for a Norgren QA/8100/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/61/320?

Enquire Now

FAQs

Before mounting, verify the mounting pattern matches standard Norgren end blocks and rail profiles. Confirm bore alignment, rail type, and end-cap orientation. Use the CAD download to confirm hole spacing and torque specifications, then connect air lines with appropriate fittings. Ensuring correct orientation minimizes wear and improves repeatability over long runs.

The unit features a 100 mm cylinder bore and a 320 mm stroke, designed as a guide block roller bearing style 61. It is a pneumatic actuator optimized for precise linear motion in automation and control systems, with compatibility to Norgren mounting standards and standard air connections for straightforward integration.

Yes. Its 100 mm bore and 320 mm stroke provide reliable reach and stroke consistency, making it well-suited for packaging, assembly, and machine-tool applications. For food-grade or washdown environments, select compatible seals and IP-rated variants, and verify compatibility with your rail and end-block ecosystem.

In automation, CE compliance and SIL-capable safety interfaces are common considerations, alongside IP-rated protections for environmental harshness. While this model aligns with typical industry expectations, confirm with the supplier or datasheet for the exact certification scope and any region-specific requirements before deployment.

Upgrading to QA/8100/61/320 can reduce downtime through improved alignment stability and lower wear, leading to higher machine uptime and throughput. The 320 mm stroke and 100 mm bore support efficient cycle times, while easy installation and reliable supplier support shorten commissioning and maintenance lead times, delivering tangible productivity gains.