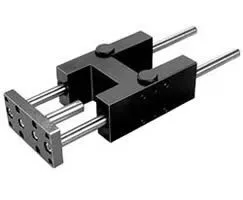

Norgren QA/8100/61/400 Guide Block - 100 mm bore

Part Number: QA/8100/61/400

Quick Summary

Norgren QA/8100/61/400 is a guide block pneumatic actuator delivering precise linear motion for automation systems. Operators often struggle with misalignment, wear, and limited mounting space when using longer strokes or non-optimized guidance. When selecting a cylinder for critical lines, consider certifications and standards that support reliability and safety; CE compliance and protected IP ratings are common expectations, and SIL-ready configurations may be requested for safety‑critical applications. This model’s 100 mm bore and 400 mm stroke address medium- to long-travel needs while maintaining compact form. CAD resources and installation guides help speed integration, reducing downtime and supporting repeatable, compliant assembly in industrial environments.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature → 100 mm bore cylinder design provides ample force and compact footprint, boosting machine density and reducing enclosure size. Business Impact → Higher throughput and simpler cabinet layouts translate to increased line efficiency and reduced capital cost per point of actuation. Application → Ideal for small automation cells handling precise positioning tasks with tight zoning. Feature → Roller bearing guide in a guide block configuration minimizes play and wear, improving repeatability. Business Impact → Longer service intervals and lower maintenance costs, reducing unplanned downtime. Application → Suitable for high-cycle transfer tasks in food and packaging lines where consistent motion matters. Feature → 400 mm stroke expands reach without a large physical footprint, enabling versatile part handling. Business Impact → Greater reach in pick-and-place operations, enabling multiple work zones from a single actuator. Application → Fit for mid-range transfer tasks in assembly lines needing flexible travel. Feature → Rich CAD downloads and installation guides streamline integration with existing automation ecosystems. Business Impact → Faster time-to-value, fewer integration errors, and accelerated commissioning. Application → Engineers gain confidence during retrofits and new-line builds thanks to available engineering resources.

Get a Quick Quote for a Norgren QA/8100/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/61/400?

Enquire Now

FAQs

For reliable installation, ensure a flat, rigid mounting surface with clean alignment to minimize side load. Use the guide block's roller bearing guidance to maintain straight travel and reduce wear. Leverage the provided CAD models to verify fitment within your cell and confirm compatible accessory components before procurement.

A 100 mm bore provides balanced force for stable actuation, while a 400 mm stroke offers sufficient reach for medium-distance transfers. The roller bearing guide improves repeatability and smoothness, helping maintain part placement accuracy over extended cycles. Pair with correct mounting and cushioning to optimize cycle times and reduce dynamic impact.

Yes, the 100 mm bore with a 400 mm stroke suits medium-to-high cycle environments where precise, repeatable motion is essential. The guide block roller bearing design minimizes wear, extending service life in repetitive pick-and-place and transfer tasks. Confirm compatibility with your cycle rate and mounting constraints using the downloadable CAD resources.

The listing does not specify CE or IP ratings. For exact compliance, consult the full datasheet and installation guide or contact Norgren directly. Regulatory requirements vary by region and application, so verify the specific ratings for your environment and safety standards before deployment.

CAD models enable precise digital integration, reducing design iterations and collision checks during integration. The installation guide streamlines on-site assembly, cutting commissioning time and minimizing setup errors. Together, these resources shorten time-to-value, lower risk, and improve maintenance planning for predictable operation.