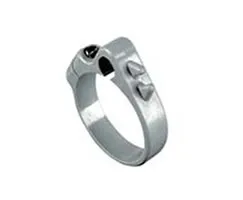

Norgren QM/33/012/22 Switch mounting brackets - 12 mm bore

Part Number: QM/33/012/22

Quick Summary

QM/33/012/22 switch mounting brackets are designed to secure 12 mm bore cylinders in compact automation installations. Engineers often face misalignment that causes wear, inconsistent actuation, and unplanned downtime. While many bracket solutions claim ruggedness, you should confirm CE compliance and IP-rated protection where required; Norgren emphasizes standards alignment across the Lintra Plus family. This mounting solution delivers a lightweight, space-saving option that helps streamline assembly, reduce field adjustments, and improve repeatable performance in automated lines.

Product Information

Cylinder diameter

12 mm

Dimensions - Height

12 mm

Dimensions - Length

5 mm

Dimensions - Width

12 mm

Weight

0.012 kg

Country of Origin

Germany

Series

Lintra Plus

Brand

IMI Norgren

Compact geometry optimized for 12 mm bore cylinders delivers a reduced envelope, enabling tighter layouts along automated conveyance and pick-and-place cells. The precise, fixed mounting improves repeatable actuator positioning, which translates to lower setup time and less downtime during changeovers. Weighing just 0.012 kg, the bracket minimizes moving mass and dynamic load on the actuator, improving response times and energy efficiency in high-cycle applications. Its lightweight construction also reduces transportation and handling costs during installation. Part of the Lintra Plus series, it ensures compatibility with Norgren’s ecosystem, simplifying procurement, spare-parts alignment, and maintenance planning for automation projects. The standardized 12 mm bore mounting works across typical pneumatic circuits, supporting rapid integration with existing manifolds and controllers. Made in Germany, this bracket reflects the precision and reliability expected in industrial control systems. Its robust design helps protect actuation points from misalignment and vibration in harsh factory environments. Documentation is readily available via CAD downloads and datasheets, enabling engineers to validate fit, generate BOMs, and accelerate approvals. The combination of compact form, known weight, and clear spec helps shorten installation times and improve traceability in quality systems.

Get a Quick Quote for a Norgren QM/33/012/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/33/012/22?

Enquire Now

FAQs

Begin by aligning the bracket with the 12 mm bore cylinder axis, ensuring the mounting holes line up with your actuator and supporting frame. Secure with the appropriate fasteners, then verify that the cylinder travels true without binding. Consult the CAD data and datasheet during layout to confirm clearances and torque requirements, ensuring repeatable actuation across assemblies.

Yes. The QM/33/012/22 is designed for 12 mm bore cylinders within the Lintra Plus family, promoting a consistent fit across standard frames. This compatibility simplifies parts sourcing, reduces integration risk, and helps maintain uniform maintenance practices across Lintra Plus installations.

Ideal for compact pneumatic feed and pick-and-place stations, end-of-line actuation, and space-constrained automation cells. The 12 mm bore compatibility, lightweight profile, and German-engineered precision support reliable switch mounting in high-cycle environments while enabling faster changeovers and easier alignments on crowded production floors.

CE compliance and IP-rated protection are commonly referenced standards for Norgren components; consult the datasheet for specific configurations. When used within approved assemblies, the QM/33/012/22 can meet typical regulatory and safety expectations in industrial environments, enabling safer operation and smoother qualification processes.

The bracket’s precise, stable mounting reduces misalignment-induced wear, minimizing downtime and maintenance costs. Its lightweight, compact design saves space and simplifies installation, contributing to faster project delivery and lower labor costs. By aligning quickly with Lintra Plus components, it also improves BOM accuracy and long-term asset traceability.