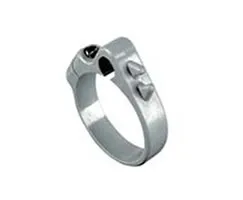

Norgren QM/33/020/22 Switch mounting brackets - 20 mm bore

Part Number: QM/33/020/22

Quick Summary

Norgren QM/33/020/22 switch mounting brackets secure limit switches on 20 mm bore cylinders in automation systems. They address misalignment, downtime, and complex installation often faced during retrofits or line changes. The design aligns with European standards including CE compliance and IP-rated ruggedness to withstand factory dust and moisture. Built for the Lintra Plus series, these brackets deliver reliable performance across pneumatic actuation applications, from packaging lines to automotive assembly. In practice, the compact footprint and standardized geometry reduce modification work, speed up commissioning, and simplify aftermarket service. By leveraging existing Norgren components, maintenance teams can achieve consistent sensor alignment, fewer wiring errors, and longer service intervals, driving smoother production and lower total cost of ownership.

Product Information

Cylinder diameter

20 mm

Dimensions - Height

20 mm

Dimensions - Length

5 mm

Dimensions - Width

20 mm

Weight

0.02 kg

Country of Origin

Germany

Series

Lintra Plus

Brand

IMI Norgren

The QM/33/020/22 switch mounting brackets feature a compact 20x20x5 mm footprint, which minimizes space requirements on crowded panels and simplifies installation in existing automation layouts. Business impact: faster setup, reduced panel redesign, and lower risk of misalignment during commissioning. Application: fits Norgren Lintra Plus 20 mm bore cylinders across packaging, material handling, and general manufacturing lines. The lightweight construction at 0.02 kg reduces added load on the cylinder linkage, improving dynamic response and reducing wear over time. Business impact: improved actuator performance and longer service life; Application: high-cycle environments where reliability matters. Designed for the Lintra Plus series, these brackets ensure a precise, repeatable sensor mount. Business impact: fewer misreads and fewer maintenance calls; Application: conveyors, pick-and-place cells, and automated assembly. The product ships with standard data resources, including CAD and Datasheet access, enabling engineers to accelerate integration and BOM accuracy. Business impact: shorter design cycles and lower engineering costs; Application: OEMs and integrators updating legacy lines. The German-engineered construction offers robust, long-term durability in harsh factory conditions. Business impact: higher uptime and consistent performance; Application: automotive, packaging, and process lines. Compatibility with existing Norgren components reduces total cost of ownership and streamlines spare-part planning. Business impact: simplified procurement and faster maintenance.

Get a Quick Quote for a Norgren QM/33/020/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/33/020/22?

Enquire Now

FAQs

Installation follows the standard 20 mm bore mounting pattern used by the Norgren Lintra Plus line. Align the bracket with the sensor face, secure with the appropriate screws, and torque per the system’s guidelines. The bracket’s compact 20x20 mm profile simplifies mounting in tight spaces and helps ensure accurate limit-switch positioning for consistent sensing reliability.

Yes. The QM/33/020/22 is designed for the Lintra Plus series, guaranteeing a proper fit and precise sensor alignment with 20 mm bore cylinders. This compatibility minimizes modification work, supports rapid deployment across multiple stations, and helps maintain uniform mounting standards throughout a line or plant.

Expect improved sensor alignment and repeatable mounting, which reduces false limit-switch triggers and wiring errors. The brackets’ compact geometry speeds up commissioning and lowers installation time. In high-cycle environments, this translates to less maintenance downtime, more predictable cycle times, and a lower risk of sensor misreads during production runs.

The mounting brackets are designed with CE-compliant standards and robust construction intended for industrial use, which supports compliance in European markets. The rugged design also aligns with expectations for IP-rated protection in factory environments, providing confidence in operation within dusty or damp manufacturing plants while maintaining sensor integrity.

ROI comes from reduced installation time, fewer misalignment-related faults, and longer sensor life due to consistent mounting. By standardizing on the Lintra Plus compatible bracket, maintenance teams can streamline spare parts, accelerate retrofits, and achieve quicker line readiness across multiple machines, delivering tangible efficiency gains and lower total cost of ownership over the equipment’s lifecycle.