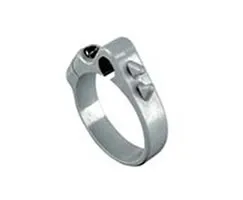

Norgren QM/33/025/22 Switch Mounting Bracket - 25 mm Bore

Part Number: QM/33/025/22

Quick Summary

QM/33/025/22 switch mounting bracket enables precise 25 mm bore cylinder alignment in automation systems. Engineers often struggle with misalignment that leads to slower cycles, unexpected wear, and inconsistent performance during panel mounting. Certification details are documented in the datasheet and commonly cover CE compliance, IP ratings, and SIL considerations for automation components; verify these in your purchasing specs. With Lintra Plus compatibility and readily available CAD resources, this bracket reduces installation time, supports reliable operation, and contributes to lower maintenance costs. Originating from Germany, IMI Norgren's engineering heritage reinforces durability across harsh industrial environments.

Product Information

Cylinder diameter

25 mm

Dimensions - Height

25 mm

Dimensions - Length

5 mm

Dimensions - Width

25 mm

Weight

0.025 kg

Country of Origin

Germany

Series

Lintra Plus

Brand

IMI Norgren

Feature: 25 mm bore compatibility ensures precise alignment between the bracket and standard 25 mm cylinder assemblies. Business Impact: improves cycle accuracy and reduces internal wear, leading to longer service life and fewer in-process adjustments. Application: ideal for panel-mounted automation where compact, reliable alignment is critical. Feature: Lintra Plus series compatibility brings proven engineering quality and interoperability with other Norgren components. Business Impact: reduces system integration risk and simplifies spare parts procurement. Application: suitable for robotics cells and automated packaging lines that rely on consistent cylinder positioning. Feature: Lightweight design at 0.025 kg minimizes added inertia on moving parts. Business Impact: supports faster response times and energy efficiency in high-speed applications. Application: suitable for compact automation assemblies with frequent actuation. Feature: Compact dimensions (25 mm height, 5 mm length, 25 mm width) enable installation in tight enclosures. Business Impact: enables more flexible rack-and-panel layouts and easier retrofits. Application: ideal for legacy machines and new automation projects with limited space. Feature: CAD availability and datasheet access streamline engineering workflows. Business Impact: shortens design cycles, reduces BOM errors, and accelerates time-to-production. Application: effective for engineers integrating switch mounting brackets into CAD models and bill of materials.

Get a Quick Quote for a Norgren QM/33/025/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/33/025/22?

Enquire Now

FAQs

Yes. The QM/33/025/22 is designed specifically for 25 mm bore cylinder assemblies and the Lintra Plus family. When selecting, verify the cylinder diameter, mounting pattern, and lever clearance to ensure a clean fit. Access the CAD model and datasheet to confirm hole spacing and orientation before purchase.

You can expect enhanced alignment accuracy, reduced misalignment-related wear, and more consistent cycling. The lightweight 0.025 kg design minimizes added inertia, supporting faster actuation in high-speed lines. The bracket also helps maintain repeatable positioning across cycles, reducing downtime caused by misalignment adjustments.

This bracket excels in manufacturing automation, robotics cells, packaging lines, and general machine integration where 25 mm bore cylinders are standard. Its compact form and compatibility with Lintra Plus components make it a good fit for control panels, pneumatic assemblies, and retrofitting projects with space constraints.

Verify CE compliance, IP ratings, and SIL considerations as applicable to your equipment and region. Certification details are typically listed in the datasheet. For procurement and safety audits, confirm these certifications with the supplier and ensure the installation adheres to your machine’s safety and reliability requirements.

The bracket contributes to longer service life by maintaining precise alignment, reducing wear, and minimizing maintenance downtime. Its compatibility with CAD workflows speeds up design iterations, decreases assembly time, and lowers total cost of ownership when used in conjunction with Lintra Plus cylinders in automated production lines.