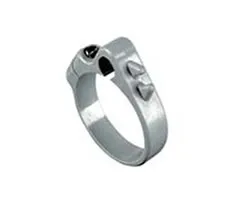

Norgren QM/33/032/22 Switch mounting brackets - 32 mm bore

Part Number: QM/33/032/22

Quick Summary

QM/33/032/22 switch mounting brackets enable secure mounting for 32 mm bore pneumatic cylinders in compact automation layouts. Engineers often contend with misalignment and space constraints when integrating sensors and limit switches into tight panels. While the data here does not list explicit certifications, CE compliance, IP-rated protection, and SIL safety considerations are critical when selecting mounting hardware for automated lines. Leveraging the Lintra Plus design and German manufacturing heritage, this bracket delivers reliable performance in demanding environments, helping reduce downtime and rework. The combination of a compact footprint and proven compatibility with the Lintra Plus series supports streamlined sourcing and faster project timelines for industrial automation projects.

Product Information

Cylinder diameter

32 mm

Dimensions - Height

32 mm

Dimensions - Length

5 mm

Dimensions - Width

32 mm

Weight

0.032 kg

Country of Origin

Germany

Series

Lintra Plus

Brand

IMI Norgren

Feature → Business Impact → Application: The 32 mm bore compatibility of the QM/33/032/22 bracket ensures precise alignment with standard pneumatic cylinders, reducing misalignment and sensor wear. This translates to longer sensor life, fewer false readings, and lower maintenance costs on high-speed lines. Feature → Business Impact → Application: The lightweight 0.032 kg construction minimizes mounting inertia, enabling quicker installation and easier field adjustments without compromising rigidity. This is especially valuable in automated packaging and assembly cells where rapid changeovers are common. Feature → Business Impact → Application: With dimensions of 32 x 32 mm and a 5 mm length, the bracket fits tight panel spaces while maintaining stable sensor positioning, improving reliability in compact control panels. Feature → Business Impact → Application: Part of the Lintra Plus series and manufactured in Germany, the bracket offers consistent quality, supply chain reliability, and compatibility with Norgren’s broader control systems, supporting scalable automation. Feature → Business Impact → Application: Availability of CAD and Datasheet downloads streamlines engineering validation, enabling quicker approvals and compliant installations across OEM and end-user sites. Feature → Business Impact → Application: By matching the 32 mm bore standard, the bracket minimizes part variety, reducing procurement complexity and inventory costs in multi-line factories.

Get a Quick Quote for a Norgren QM/33/032/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/33/032/22?

Enquire Now

FAQs

Begin by verifying the bracket is designed for a 32 mm bore cylinder and aligns with the sensor mounting position. Align the bracket with the cylinder axis, fasten with appropriate screws, and ensure the sensor is positioned for clean signal capture. Refer to the CAD drawing and the Datasheet for recommended mounting torque and screw sizing to avoid overtightening and component damage.

The bracket provides precise sensor alignment, a lightweight and compact form factor, and rugged German engineering from the Lintra Plus line. These traits translate to reduced misreads, faster installation, lower maintenance, and consistent performance across high-cycle applications such as packaging lines and automated assembly cells.

Yes. QM/33/032/22 is part of the Lintra Plus family and is designed to fit 32 mm bore cylinders, ensuring compatible mounting and reliable sensor integration within standard Norgren pneumatic systems. For best results, cross-check the Datasheet and CAD resources to confirm fit with your specific actuator and control modules.

Critical considerations include CE marking for EU compliance and appropriate IP-rated protection for the operating environment. While this data set lists country of origin as Germany and standard Lintra Plus lineage, verify the certificate scope in the Datasheet or with the supplier to ensure alignment with your safety and regulatory requirements.

Expected ROI stems from reduced downtime due to reliable mounting, quicker installation and changeovers, and lower maintenance costs from precise alignment. The availability of CAD/Datasheet resources accelerates validation and commissioning, shortening project timelines and enabling faster payback on automation investments.