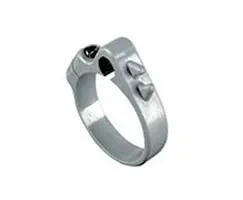

Norgren QM/33/432/22 Switch mounting brackets - 32 mm bore

Part Number: QM/33/432/22

Quick Summary

Norgren QM/33/432/22 is a switch mounting bracket for 32 mm bore cylinders used in automation and control systems. Engineers often struggle with precise alignment, quick assembly, and reliable integration when adding brackets into Lintra Plus components. Certifications like CE, SIL, and IP ratings are not specified in the provided data; verify with the manufacturer datasheet for your compliance needs. With its compact footprint and German engineering, it supports scalable automation, faster setup, and dependable actuation in pneumatic lines. This solution aligns with 32 mm bore actuators and Lintra Plus modules, helping teams reduce mounting time while improving system uptime and reliability.

Product Information

Cylinder diameter

32 mm

Dimensions - Height

10 mm

Dimensions - Length

32 mm

Dimensions - Width

32 mm

Weight

0.02 kg

Country of Origin

Germany

Series

Lintra Plus

Brand

IMI Norgren

Feature: Compact 32x32 mm footprint with a 10 mm height. Business Impact: Enables space-saving installations in tight panels and crowded control cabinets, reducing enclosure footprint. Application: Ideal for compact automation lines requiring precise bracket placement around 32 mm bore cylinders. Feature: Lightweight construction at 0.02 kg. Business Impact: Lowers inertial load and simplifies handling during installation, contributing to faster assembly and reduced technician fatigue. Application: Effective in high-cycle applications where weight savings translate to longer component life. Feature: 32 mm bore cylinder compatibility. Business Impact: Ensures consistent alignment and repeatable actuation with standard 32 mm actuators, improving reliability across cycles. Application: Suitable for Lintra Plus pneumatic systems in packaging, material handling, and manufacturing lines. Feature: Lintra Plus series compatibility. Business Impact: Facilitates plug-and-play integration with Norgren components, reducing engineering time and risk during system upgrades. Application: Supports scalable configurations in automation and control environments. Feature: German origin and build quality. Business Impact: Delivers robust, long-lasting performance with tight tolerances, lowering maintenance intervals and total cost of ownership. Application: Preferred in industrial environments demanding high reliability and consistent fabrication standards.

Get a Quick Quote for a Norgren QM/33/432/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/33/432/22?

Enquire Now

FAQs

The QM/33/432/22 is designed to mount 32 mm bore cylinders within Norgren Lintra Plus setups. To install, verify cylinder diameter, align the bracket with the mounting surface, and secure using the appropriate fasteners specified in the Norgren datasheet. Ensure the bracket footprint (32x32 mm) fits your panel cutouts to maintain proper alignment and stroke consistency.

The bracket features a 32 mm cylinder diameter, with overall dimensions of 32 mm length, 32 mm width, and 10 mm height. It has a nominal weight of 0.02 kg. These specifications support a compact, low-inertia mounting solution that minimizes added mass to the moving assembly and aids in stable switch actuation.

Yes. The QM/33/432/22 is part of the Lintra Plus family and is intended for 32 mm bore cylinders, making it a natural fit for packaging, material handling, and other automated lines. Its compact form factor and lightweight construction support quick installations and consistent actuator alignment in high-throughput environments.

The provided data does not list specific certifications for this bracket. For compliance requirements such as CE, SIL, or IP ratings, consult the official Norgren datasheet or contact Norgren technical support to verify current certifications and suitability for your regional standards and safety programs.

Security and reliability of mounting reduce misalignment and actuator wear, leading to lower maintenance needs and less unscheduled downtime. The bracket’s light weight, compact footprint, and Lintra Plus compatibility streamline installation and future upgrades, delivering a faster time-to-value and improved overall equipment effectiveness (OEE) in automated lines.