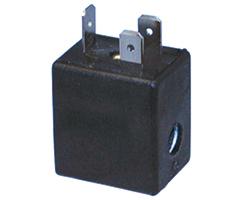

Norgren QM/48/19J/28 Spare Coils - Coil Code 19J

Part Number: QM/48/19J/28

Quick Summary

Norgren QM/48/19J/28 spare coils provide reliable actuation for modular valve manifolds in automation lines. Unplanned downtime from coil failure can disrupt production and drive maintenance costs higher. Look for CE compliance and IP protection in installations, and verify SIL safety considerations per the datasheet for critical processes. This accessory aligns with standard Norgren coil specifications to help engineers simplify inventory, shorten repair times, and maintain consistent performance across multiple machines. For procurement teams, it supports reduced spares inventory while ensuring compatibility with the QM/48 series, enabling smoother changeovers and faster commissioning across OEM plants.

Product Information

Coil Code

19J

Brand

IMI Norgren

Feature: Coil Code 19J compatibility with the QM/48 valve range. Benefit: Ensures rapid, accurate replacement and predictable actuation, reducing downtime and simplifying spare part strategy for OEMs and aftermarket service. Application: Service technicians maintaining modular pneumatic systems in packaging lines and material handling. Feature: Brand alignment with IMI Norgren quality. Benefit: Access to proven reliability and global support networks, minimizing risk in critical production environments. Application: OEMs integrating standard spare coils across multiple machines for consistency. Feature: Availability of the official datasheet. Benefit: Enables correct installation, electrical compatibility checks, and compliance verification, supporting audit readiness. Application: Procurement and QA teams validating part specs before purchase. Feature: Spare coil designed for QM/48 family. Benefit: Streamlined inventory with a common replacement part across the line, reducing stocking breadth and speeding maintenance. Application: OEMs and end-users deploying multi-asset pneumatic controls. Feature: Compatibility and installation advantages. Benefit: Simplified field replacements with clear part mapping to existing manifolds, minimizing commissioning time. Application: Field service in Brownfield and Greenfield automation projects. Insight: Leveraging spare coils within the QM/48 ecosystem supports cross-machine standardization, which is a well-established best practice in modern industrial plants for reliability and cost control.

Get a Quick Quote for a Norgren QM/48/19J/28

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/48/19J/28?

Enquire Now

FAQs

The QM/48/19J/28 spare coil is designed specifically for the QM/48 valve range. While it may be suitable for related configurations within the Norgren family, always verify coil code, voltage, and pinout against the relevant valve model and consult the latest datasheet before mixing parts across different series to avoid misfits or performance issues.

Coil Code 19J identifies the winding and electrical characteristics of this specific spare coil. It ensures consistent magnetic response and plunger actuation when energised, matching the corresponding QM/48 valve configurations. Using an incorrect coil code can lead to improper seating, misactuation, or reduced reliability, so confirm the code matches the target valve’s specification.

Industries employing modular pneumatic valve manifolds—such as packaging, material handling, automotive manufacturing, and general automation—benefit from having QM/48 spare coils on hand. Standardized coils reduce downtime during maintenance, simplify spares management, and support faster line changeovers across multi-asset plants.

Engineering teams should verify CE compliance and any applicable IP protection ratings for installations, depending on the operating environment and country requirements. SIL considerations may apply for critical safety applications; always consult the datasheet and regulatory guidance to ensure the coil meets the specific safety and performance standards of the application.

Keeping spare coils on-site reduces unplanned downtime by enabling rapid replacement, minimizes production stops, and lowers repair costs. Standardized compatibility with the QM/48 series means fewer part number variants to stock, improved uptime metrics, and faster commissioning across multiple machines, delivering tangible total cost of ownership benefits.