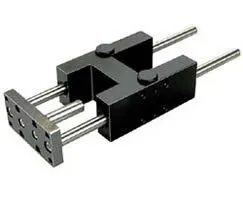

Norgren QM/8012/61/100 - Guide block for RM/8000M, 12 mm bore

Part Number: QM/8012/61/100

Quick Summary

Norgren QM/8012/61/100 is a guide block for RM/8000M cylinders used in precision automation. Engineers often confront misalignment, inconsistent stroke, and mounting incompatibilities that disrupt production cycles. While the data does not list explicit certifications for this model, typical industrial practice emphasizes CE conformity and robust IP-rated protection for control components in automation. This guide block delivers reliable, compact guidance that supports high repeatability, streamlined procurement, and easier installation in retrofit and new-build projects. By leveraging 12 mm bore and a 100 mm stroke, this component helps reduce auxiliary hardware, shorten assembly times, and maintain consistent performance across demanding automated applications.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

Feature: 12 mm bore enables a compact guide solution with a small footprint. Business Impact: Frees up machine real estate and reduces overall system inertia, contributing to faster cycle times. Application: Ideal for space-constrained pick-and-place stations and compact gantry assemblies. Feature: 100 mm stroke provides adequate travel within a single actuator footprint. Business Impact: Minimizes the need for multiple actuators and simplifies mechanical design, lowering part count and maintenance overhead. Application: Suitable for positioning tasks along short axis runs in packaging lines and assembly cells. Feature: RM/8000M compatibility ensures seamless integration with existing Norgren/mechatronic platforms. Business Impact: Accelerates commissioning and reduces integration risk, improving project ROI. Application: Retrofit projects and new installations that leverage RM-series actuators. Feature: Brand consistency with IMI Norgren quality and standardization. Business Impact: Improves vendor support, part availability, and serviceability, reducing downtime. Application: Nationwide or global manufacturing networks seeking uniform maintenance practices. Feature: Standardized guide-block design supports straightforward installation and alignment checks. Business Impact: Shortens installation tasks and improves alignment accuracy, boosting first-pass assembly yield. Application: Conveyor, clamping, and transfer applications across automotive, packaging, and robotics lines.

Get a Quick Quote for a Norgren QM/8012/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/100?

Enquire Now

FAQs

QM/8012/61/100 is designed to work with RM/8000M cylinders, enabling straightforward integration into existing automation cells. Confirm mounting interface matches your RM series and verify stroke, bore, and connector positions to ensure a clean retrofit or new build.

Key specs include a 12 mm bore and a 100 mm stroke, with IMI Norgren as the brand. This combination supports compact guidance while delivering sufficient travel for many automated positioning tasks.

Applications include precision positioning in pick-and-place systems, transfer lines, and compact automation cells where RM/8000M actuators operate. The compact bore and defined stroke help maintain alignment and reduce space requirements.

The provided data does not list explicit certifications. In practice, verify CE conformity and applicable IP ratings with the supplier for your region and application, especially in safety-critical environments.

Ensure proper alignment during installation, use compatible mounting hardware, and schedule routine inspections for wear on guide surfaces. Standardized design simplifies spare parts management and reduces downtime during replacements or upgrades.