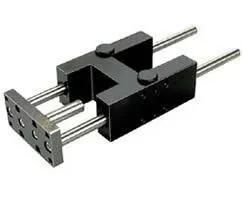

Norgren QM/8012/61/200 Guide block - 12 mm bore

Part Number: QM/8012/61/200

Quick Summary

The Norgren QM/8012/61/200 guide block provides precise motion control for RM/8000M actuators in compact automation. Engineers often struggle with misalignment, wear and limited space, which can degrade repeatability and raise maintenance costs. CE conformity and IP-rated variants are commonly expected in industrial lines, with SIL-level safety features frequently specified for safety-critical handling. For OEMs and maintenance teams, this module delivers a reliable, low-profile fit that shortens setup time and supports scalable automation, while enabling consistent cylinder performance and easier serviceability in demanding environments. By integrating this guide block, you can optimize linear motion reliability, reduce downtime, and improve overall equipment effectiveness in modern manufacturing lines.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QM/8012/61/200 guide block features a 12 mm bore, delivering precise, repeatable travel essential for accurate positioning in small-diameter pneumatic drives. This tight tolerance supports tighter assembly tolerances and reduces play, lowering scrap rates in packaging and pick-and-place lines. Application: Ideal for compact automation stages where space is at a premium. Feature → Business Impact → Application: 200 mm stroke provides extended travel within a compact footprint, enabling longer stroke without sacrificing machine footprint. This translates to fewer component changes and quicker cycle times on assembly lines that require greater reach. Application: Suitable for linear actuators in automated assembly and material handling. Feature → Business Impact → Application: RM/8000M compatibility ensures streamlined integration with existing Norgren actuators, reducing installation time and the need for adapters. Application: OEMs can accelerate retrofit projects and maintain standardization across automation cells. Feature → Business Impact → Application: Robust guide block design minimizes misalignment and wear, improving life cycles and reducing maintenance intervals. Application: Long-running positioning tasks in conveyors and inspection stations benefit from dependable alignment. Feature → Business Impact → Application: Easy inspection and straightforward mounting improve serviceability, lowering total cost of ownership. Application: Maintenance teams can perform guided replacements with minimal downtime. Feature → Business Impact → Application: Industry-standard compatibility supports spare-part availability and simplified stocking for maintenance teams. Application: Maintenance planning and procurement teams benefit from predictable maintenance windows and reduced downtime.

Get a Quick Quote for a Norgren QM/8012/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/200?

Enquire Now

FAQs

Begin by verifying mounting interfaces align with the RM/8000M actuator. Align the guide block to the actuator axis, secure with the correct mounting hardware, and ensure the bore aligns with the load path to prevent side loads. Check for smooth, rattle-free movement and verify stroke reach with the mechanical stop or end-of-travel sensors. Lubrication and periodic inspection reduce wear and maintain accuracy over time.

Key specs include a 12 mm cylinder bore and a 200 mm stroke, designed as a guide block for RM/8000M actuators. The model number is QM/8012/61/200, produced by IMI Norgren, suitable for compact automation applications where precise linear motion is required.

Yes. The 12 mm bore offers tight tolerances and the 200 mm stroke enables controlled, repeatable travel within a compact footprint. When paired with RM/8000M actuators, it supports accurate part handling, alignment-critical pick-and-place tasks, and repeatable product positioning essential for packaging lines.

In typical industrial deployments, CE conformity and IP-rated protection are common expectations for pneumatic guide blocks, with SIL-rated safety features often specified for safety-critical lines. Always verify the specific certification package with your supplier and ensure compatibility with your plant’s safety and regulatory requirements.

The combination of precise 12 mm bore and 200 mm stroke reduces misalignment and wear, leading to higher repeatability and longer service intervals. Reduced downtime, faster changeovers, and easier maintenance collectively contribute to lower operating costs and improved line productivity over the product lifecycle.