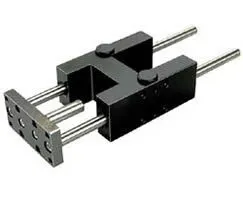

Norgren QM/8012/61/250 Guide block - 12 mm bore

Part Number: QM/8012/61/250

Quick Summary

Norgren QM/8012/61/250 guide block is a precise linear guidance solution for RM/8000M actuators used in automation and control systems. Engineers often confront misalignment, wear, and maintenance challenges in long-stroke pneumatic setups. In regulated markets, CE compliance and rugged IP-rated protection are common expectations for automation components, while SIL safety levels are sometimes specified for controls. Choosing this guide block helps improve alignment accuracy, reduces wear, and extends service life, delivering lower maintenance costs and higher line uptime. In addition to a 12 mm bore and 250 mm stroke, it integrates smoothly with the RM/8000M family, supporting efficient, repeatable motion in industrial environments.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

Feature: The QM/8012/61/250 offers a 12 mm bore and a 250 mm stroke within a compact guide block format. Business impact: This combination delivers precise linear guidance with a reduced footprint, enabling tighter machine layouts and higher axis density. Application: Ideal for RM/8000M actuator assemblies in pick-and-place, packaging, and material-handling lines where consistent stroke and position accuracy are critical. Feature: Designed as a dedicated guide block for RM/8000M systems provides straightforward mounting and alignment. Business impact: Reduces installation time and obsolescence risk by using a standardized interface, lowering commissioning costs and improving spare parts planning. Application: OEM lines and retrofit projects benefit from faster setup, predictable performance, and easier integration with existing pneumatic circuits. Feature: Precision-guiding elements and controlled movement minimize deflection under load. Business impact: Lower positional drift translates to tighter tolerances, higher repeatability, and less scrap in high-volume manufacturing. Application: Suitable for press-fed equipment, label applicators, and conveyor lines where repeatable actuation directly affects throughput. Feature: Robust design supports high-cycle operation and long service life. Business impact: Reduces maintenance frequency and cost, increases line uptime, and improves total cost of ownership. Application: Harsh factory floors with dust and vibration, where dependable guidance blocks keep motion consistent. Feature: Seamless compatibility with IMI Norgren ecosystem and common fittings. Business impact: Streamlines procurement, simplifies maintenance, and ensures compatibility with related actuators, sensors, and mounting hardware. Application: New builds and spares strategy in automation and control systems.

Get a Quick Quote for a Norgren QM/8012/61/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/250?

Enquire Now

FAQs

The QM/8012/61/250 is designed for straightforward mounting on RM/8000M assemblies. Verify the 12 mm bore and 250 mm stroke, align the guide block with the actuator's mounting pattern, and fasten with recommended hardware. After mounting, perform a slow, full travel test to confirm smooth, resistance-free movement and repeatable positioning. Maintain proper gap clearance and re-check after initial cycles.

Key specifications are a 12 mm cylinder bore and a 250 mm stroke, allowing a compact yet long travel path. The block is designed for RM/8000M systems and aligns with standard mounting interfaces to simplify integration. It delivers repeatable motion with minimal deflection, ideal for applications requiring precise positioning and consistent cycle times in automated lines.

Yes, the QM/8012/61/250 is well-suited for high-cycle packaging lines where reliable, repeatable guidance reduces drift and scrap. Its 12 mm bore and 250 mm stroke support compact layouts while maintaining accurate positioning over many cycles. For best results, pair it with compatible sensors and mountings from the Norgren RM/8000M ecosystem.

Certification details are product-region dependent. Verify CE compliance, IP ratings for environmental protection, and any SIL requirements with the supplier or distributor. Request formal certification documentation for your specific shipment and confirm compatibility with your facility's safety and quality programs before deployment.

By delivering precise alignment and reducing deflection, wear is minimized and maintenance frequency decreases, translating to reduced downtime. The result is higher line uptime and lower total cost of ownership. The compact 12 mm bore and 250 mm stroke also support longer service life with consistent performance across multiple automation lines.