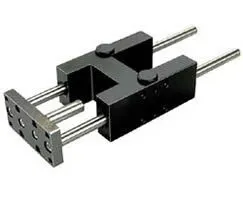

Norgren QM/8012/61/320 Guide Block - 12 mm Bore

Part Number: QM/8012/61/320

Quick Summary

The Norgren QM/8012/61/320 guide block enables precise, guided motion for RM/8000M cylinders in automated production lines. Engineers often face misalignment and wear in sliding guides, which can cause unexpected downtime and scrap. Key certifications and standards, such as CE marking and safety-focused ratings, are important for compliant integration, and many buyers also look for SIL safety compatibility and IP-rated protection in harsher environments. This compact 12 mm bore block delivers repeatable positioning with straightforward installation, helping shorten commissioning time and reduce inventory variety. By choosing a compatible Norgren system, manufacturers gain reliable performance, easier sourcing, and better overall equipment reliability, translating to lower lifecycle costs and higher line throughput.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

Feature: 12 mm bore guide block delivers compact, low-mass linear guidance with tight tolerance control. Business impact: improves repeatable positioning and reduces inertial load on actuators, boosting cycle speeds and energy efficiency. Application: supports RM/8000M cylinders in packaging lines and automated assembly cells. Feature: RM/8000M compatibility and standard mounting patterns. Business impact: decreases commissioning time and minimizes the need for custom brackets, lowering procurement risk and spare-part variety. Application: ideal for retrofit projects and new line builds across automotive, consumer electronics, and packaging sectors. Feature: Durable construction reduces wear under high-cycle operation. Business impact: extends service life, lowers maintenance costs, and improves overall equipment effectiveness. Application: suitable for high-speed pick-and-place machines and continuous-motion conveyors in harsh industrial environments. Feature: Easy alignment and integration with existing Norgren components. Business impact: minimizes downtime during changeovers and simplifies adjustments on the shop floor. Application: helpful for OEMs delivering turnkey automation cells. Feature: Consistent supply chain with global support. Business impact: reduces downtime and ensures maintenance planning with readily available spare parts. Application: supports long-term automation programs with predictable upkeep.

Get a Quick Quote for a Norgren QM/8012/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/320?

Enquire Now

FAQs

For installation, use the standard Norgren mounting pattern compatible with RM/8000M assemblies. Ensure proper alignment using established dowel pins, secure with correctly torqued M4/M5 fasteners, and verify smooth rail interaction to minimize play. The block should be mounted to maintain a straight axis, preserving repeatability and reducing edge wear in high-cycle environments.

A 12 mm bore supports compact, lower-mass guidance suitable for many automation tasks. Load capacity is governed by the RM/8000M combination and the slider’s guidance surface; while offering good precision, higher lateral loads or misalignment can increase wear. For best results, ensure clean mounting surfaces, correct alignment, and controlled speeds to minimize wear over time.

Yes, for many high-speed packaging and assembly applications, the 12 mm bore guide block provides repeatable, precise guidance with easy installation. To maximize performance, pair it with compatible Norgren components, maintain clean guides, and implement proper alignment during line changeovers to preserve throughput and product quality.

Key certifications to verify include CE marking for European compliance, safety-related considerations like SIL compatibility where integrated with safety systems, and IP-rated protection for harsh environments. Always confirm the exact part variant with the supplier, as certification availability can vary by market and configuration.

Expect reduced downtime through stable alignment and longer intervals between maintenance due to robust guidance surfaces. The ROI comes from lower spare-part variety, faster changeovers, and improved line OEE. Regular inspection and clean mounting surfaces help sustain performance, while the broader Norgren ecosystem supports long-term availability and technical assistance.