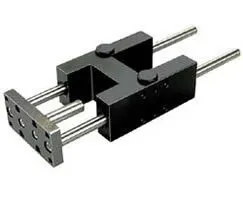

Norgren QM/8012/61/400 Guide Block - 12 mm Bore

Part Number: QM/8012/61/400

Quick Summary

QM/8012/61/400 guide block enables precise RM/8000M motion in automation systems. Engineers often struggle to maintain consistent slide accuracy and smooth travel across long strokes. Typical deployments benefit from CE marking and robust IP protection in compatible variants, reinforcing safety and reliability in harsh environments. By standardizing on this Norgren block, maintenance teams reduce setup time and facilitate scalable automation across lines, delivering measurable improvements in uptime and throughput. This solution also integrates smoothly with the Norgren Automation & Control Systems ecosystem, offering a familiar interface for technicians and procurement teams seeking dependable industrial automation components. Its 12 mm bore and 400 mm stroke deliver versatility across Cartesian axes, enabling faster line changes with reduced rework.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

The 12 mm bore and 400 mm stroke establish a precise linear motion profile that reduces travel variation under repeated cycling. This translates to improved repeatability and smoother acceleration across automation tasks, cutting defect rates and cycle times. In RM/8000M driven lines, this geometry supports reliable pick-and-place and transference operations. Seamless compatibility with RM/8000M and Norgren accessory ecosystems lowers installation risk. Clear mounting patterns and standard interfaces minimize alignment issues, speeding up retrofits and line expansions while preserving reliability in demanding plants. Maintenance-friendly design supports quicker inspections and easier part changes. Operators report lower labor costs and less unscheduled downtime when standard blocks are used across multiple lines. Using a shared component like QM/8012/61/400 simplifies spares management and supplier lead times, translating into lower total cost of ownership and easier cross-site deployments for OEMs and end users. On certified variants, CE compliance and IP-rated protection levels help meet site safety requirements and industrial guidelines.

Get a Quick Quote for a Norgren QM/8012/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/400?

Enquire Now

FAQs

To install QM/8012/61/400 with an RM/8000M system, align the guide block to the actuator rail and secure using the standard mounting pattern, then verify 12 mm bore compatibility with the cylinder housing. Confirm proper clevis or end-attachment, torque values, and lubrication intervals to prevent binding. Perform a test run before full production.

With a 12 mm bore and 400 mm stroke, the QM/8012/61/400 delivers stable travel and repeatable positioning under high cycle demands. This geometry reduces lateral play and enables consistent acceleration profiles, improving throughput and part quality. In packaging or assembly lines, technicians can tune feeds for predictable dwell times and fewer rework events.

QM/8012/61/400 is designed to integrate with Norgren RM and standard accessory families, simplifying compatibility checks during procurement. The 12 mm bore aligns with common pneumatic cylinders, while the 400 mm stroke matches typical long-travel applications. You can leverage existing mounting adapters, seals, and end supports to accelerate retrofits and maintain consistent performance.

Certification scope for this guide block depends on configuration; typical industrial deployments reference CE marking for safety compliance and IP-rated protection levels for environmental endurance. When selecting variants, verify the specific protection class and any additional standards required by your facility, such as machinery directives or sector-specific codes. Consult Norgren catalogs for certified options.

By reducing misalignment risk and enabling straightforward replacements, the QM/8012/61/400 lowers routine maintenance and minimizes unplanned downtime. The 12 mm bore and 400 mm stroke help standardize parts across lines, improving spares availability. Over multiple production cycles, this translates to lower maintenance labor costs and faster changeovers, boosting overall equipment effectiveness.