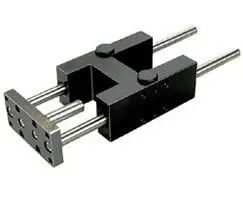

Norgren QM/8012/61/50 Guide Block - 50 mm Stroke

Part Number: QM/8012/61/50

Quick Summary

Norgren QM/8012/61/50 guide block enables precise linear actuation in compact automation systems. If misalignment, stroke variability, or installation complexity is slowing your RM/8000M configurations, this unit helps streamline assembly and boost repeatability. CE conformity supports European compliance, with IP-rated variants available and SIL considerations determined by configuration. By simplifying mounting and ensuring consistent motion, you reduce downtime and procurement headaches while maintaining reliability across automation lines. This solution also aligns with standards-driven environments, offering compatibility with modular RM components and easy field-service maintenance.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

12 mm bore delivers tight guidance with minimal side load, enabling high-precision motion in compact spaces. The bore size helps reduce lateral play that can degrade repeatability on small actuators. This is especially valuable in pick-and-place and valve-actuation modules where accuracy directly affects throughput. 50 mm stroke provides meaningful travel without adding length to the assembly, increasing reach for small robot grippers and line-side actuators. The extended stroke supports multiple positions per cycle, reducing the need for additional linkage and synchronization. In practice, you gain smoother end-of-stroke cycling and fewer setup adjustments, improving line efficiency in packaging and assembly environments. RM/8000M compatibility simplifies installation with standard mounting patterns and fixings, cutting engineering effort and risk. The guide block integrates with existing Norgren RM components, so you can reuse rail assemblies and pneumatic fittings. This minimizes spare parts inventory and accelerates project timelines, even on retrofit installations. Robust construction and low-friction seals deliver long service life in demanding factory environments, lowering maintenance intervals and replacement costs. The component’s modular design eases inspection and field service, while consistent performance reduces rework in high-volume lines. You also benefit from predictable cycle times, supporting lean manufacturing goals. From a compliance perspective, CE conformity supports European deployments, and many configurations offer IP-rated protection and SIL considerations as applicable. This transparency helps procurement teams meet regulatory demands without sacrificing performance. In short, the QM/8012/61/50 guide block supports reliable automation with clear total-cost-of-ownership benefits.

Get a Quick Quote for a Norgren QM/8012/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/50?

Enquire Now

FAQs

Install the guide block by aligning it to the RM/8000M rail, secure with standard fixings, and connect the pneumatic supply. Ensure the 12 mm bore aligns with the actuator piston and verify stroke occurs within the 50 mm travel. Check for smooth movement and re-torque mounting screws after initial cycling.

Key factors include bore tolerance, stroke length, and seal material. Ensure clean air supply, correct lubrication where specified, and proper alignment with minimal friction. Regular inspection of guide surfaces and seals reduces play and improves repeatability, enabling faster, more consistent cycles on packaging or assembly lines.

The block is designed for compact pneumatic actuation within RM configurations. Availability of IP-rated variants and suitability for wet environments depends on the specific build. Verify the exact IP rating from the datasheet and select corrosion-resistant materials when operating in washdown or humidity-prone environments.

Look for CE conformity for European markets and confirm any IP or SIL requirements with the supplier. Certification status can vary by configuration; always check the latest datasheet and manufacturer declarations to ensure your project meets regulatory standards and safety guidelines.

Though ROI depends on application, this guide block can reduce downtime through repeatable actuation and fewer misloads. Maintenance is typically straightforward due to robust seals and modular design; anticipate longer service life and lower spare-part costs on high-cycle lines like packaging or automated assembly.