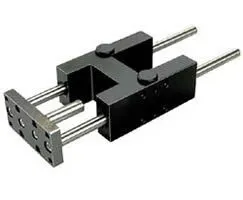

Norgren QM/8012/61/500 Guide Block - 12 mm Bore

Part Number: QM/8012/61/500

Quick Summary

QM/8012/61/500 guide block provides precise linear guidance for RM/8000M actuators in automated manufacturing. Engineers often battle misalignment, wear, and downtime when guides don’t track accurately, reducing cycle efficiency. Certification details aren’t listed here, but typical engineering specs emphasize CE compliance and IP protection for rugged environments. Choosing this block supports predictable alignment, reduces maintenance intervals, and lowers total cost of ownership by harmonizing with RM-series parts. In practice, 12 mm bore and 500 mm stroke deliver compact, high-precision guidance suitable for automation lines, robotics feeders, and packaging cells. This alignment capability also simplifies installation, improves repeatability, and helps supply chains maintain consistent part compatibility across Norgren RM components.

Product Information

Cylinder diameter

12 mm

Brand

IMI Norgren

Feature: 12 mm bore with 500 mm stroke provides precise travel and repeatability. Impact: Enables accurate positioning in tight automation cells, reducing cycle time and scrap. Application: RM/8000M guide integration in high-throughput packaging lines. Feature: Direct compatibility with RM/8000M actuators simplifies installation and spare parts planning. Impact: Cuts setup time and inventory footprint, accelerating line start-ups. Application: OEM automation builds and retrofit projects. Feature: Robust guide block construction supports consistent performance in harsh industrial environments. Impact: Longer maintenance intervals and lower total cost of ownership. Application: Food & beverage, automotive assembly, and electronics packaging lines. Feature: Alignment-centric design reduces wear on piston rods and bearings. Impact: Minimizes replacement costs and downtime. Application: High-cycle pick-and-place and precision assembly tasks. Feature: Compact form factor with straightforward mounting options. Impact: Space-efficient integration in constrained machine layouts. Application: Robotic grippers, fixture-based automation, and conveyors. These benefits are reinforced by compatibility with Norgren RM-series products, helping manufacturers standardize on a single supplier ecosystem, while long-term maintenance planning becomes simpler and more predictable.

Get a Quick Quote for a Norgren QM/8012/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8012/61/500?

Enquire Now

FAQs

Installation begins with verifying RM/8000M compatibility, then aligning the guide block to the actuator’s mounting face and securing with the recommended fasteners. Ensure bore alignment is perpendicular to the movement axis and torque settings match the supplier's guidelines. A test travel should confirm smooth operation, with re-tightening after settling to prevent drift and ensure repeatability across cycles.

The product features a 12 mm cylinder bore and a 500 mm stroke, designed for RM/8000M actuators. It’s branded as IMI Norgren, intended as a high-precision guide block within automation and control systems. These specs support compact yet long-travel guidance suitable for automotive, packaging, and assembly lines in industrial environments.

Yes. The 12 mm bore and 500 mm stroke configuration offers reliable, repeatable guidance for high-cycle operations common in packaging and material handling. When integrated with RM-series components, it supports consistent positioning, reduces wear on clearance surfaces, and helps maintain throughput targets over extended production runs.

Certification details are not specified in the provided data. For regulated environments, verify with the supplier whether this guide block or its RM/8000M integration meets CE marking and any industry-specific standards, and confirm SIL requirements if the use-case involves safety-critical cycles.

Expect improved alignment accuracy and reduced wear on moving parts, leading to longer service intervals and lower downtime. Compatibility with RM-series components minimizes part harmonization and spare-parts inventory, translating to lower total cost of ownership. In high-throughput lines, these factors collectively enhance uptime and predictable maintenance planning.