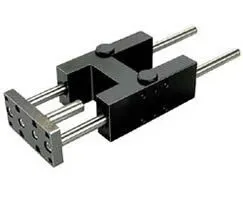

Norgren QM/8020/61/100 Guide Block - 100 mm Stroke

Part Number: QM/8020/61/100

Quick Summary

QM/8020/61/100 guide block is a precision linear guidance solution for pneumatic actuators in automation systems. Selecting this component helps address alignment and travel consistency that often bottleneck cycle times. In industrial controls, standards such as CE conformity, IP ratings, and SIL risk considerations are commonly evaluated to ensure safety and environmental resilience. By pairing this guide block with RM/8000M actuators, you gain predictable performance, reduced maintenance, and lower total cost of ownership while enabling reliable, high-throughput operation in automation lines.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 20 mm bore provides tight, controlled guidance, reducing lateral play and improving repeatability, which translates to higher precision in robotic pick-and-place tasks and accelerated throughput in assembly lines. Application: use with RM/8000M for consistent stroke and position control in packaging and material handling. Feature → Business Impact → Application: 100 mm stroke offers ample travel for compact automation cells, enabling longer reach without additional components, lowering integration complexity and stocking needs. Application: suitable for compact transfer systems in automotive component assembly. Feature → Business Impact → Application: compatibility with the RM/8000M family streamlines installation and reduces engineering time, delivering faster line upgrades and lower project risk. Application: retrofit projects and new lines in factory automation. Feature → Business Impact → Application: robust guide-block design supports simple maintenance and long service life, minimizing downtime and spare-parts costs. Application: continuous production lines in electronics manufacturing. Feature → Business Impact → Application: straightforward mounting and alignment fosters reliability in demanding environments, addressing common objections about installation complexity and system downtime. Application: food and beverage handling lines requiring clean, reliable guidance.

Get a Quick Quote for a Norgren QM/8020/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/100?

Enquire Now

FAQs

To ensure proper installation, verify bore alignment with the RM/8000M actuator, secure mounting with the correct fasteners, and confirm the guide block sits square to the guide rail. Apply a light, consistent lubricant to moving surfaces and torque hardware to manufacturer recommendations to minimize play and maximize repeatability in automation lines.

Expect high-precision guidance with minimized side-load induced play, enabling repeatable positioning across multiple cycles. The 100 mm stroke accommodates typical short-travel automation tasks while maintaining compact cell footprints. This combination supports reliable throughput in pick-and-place and transfer applications with reduced wear over time.

Suitability depends on environmental conditions and enclosure measures. While the guide block provides robust mechanical guidance, ambient dust, moisture, and temperature can affect performance. For harsh environments, consider additional sealing, enclosure protection, or enclosure-grade components, and verify any required IP rating or corrosion resistance for your specific application.

The design promotes easy mounting and straightforward alignment, reducing setup time and downtime during line changes. With longer wear life and fewer misalignments, maintenance intervals extend, spare parts usage decreases, and overall ROI improves as production uptime increases and service intervals become predictable.

Ensure mounting surfaces are clean and flat, align the block with the RM/8000M axis before tightening, and use proper fasteners with correct torque. Maintain a consistent lubrication schedule on moving components, protect the assembly from contamination, and verify travel limits do not exceed the stroke to prevent mechanical binding during operation.