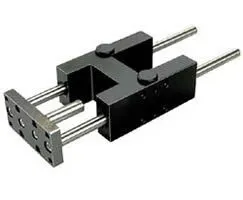

Norgren QM/8020/61/160 Guide Block - 20 mm Bore, 160 mm Stroke

Part Number: QM/8020/61/160

Quick Summary

Norgren QM/8020/61/160 is a guide block used with RM/8000M assemblies to deliver precise linear guidance in pneumatic automation applications. Engineers often contend with misalignment, side loads, and inconsistent travel that degrade cycle times and increase maintenance. This model is designed to minimize those risks by providing a stable guide path for compact actuators. While specific certifications are not listed in the data, controls and automation components in this class typically pursue CE compliance for safety and EMC, with IP-rated variants available depending on the environment. In practice, integrating this guide block can improve repeatability, reduce wear, and help you meet production targets without sacrificing uptime. Secondary benefits include compatibility with existing Norgren RM/8000M setups and streamlined maintenance planning.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

20 mm bore and a 160 mm stroke define the core geometry of the QM/8020/61/160 guide block, delivering compact yet robust guided motion for RM/8000M actuators. This precise cylinder geometry translates into repeatable travel and predictable cycle times, making it ideal for space-constrained automation lines where accurate positioning directly impacts throughput and quality. Guided alignment reduces lateral movement and side loads on actuators, lowering wear and extending service life. In practice, this translates to lower maintenance costs and fewer unexpected downtime events on conveyors, transfer lines, and assembly cells that demand high-precision motion control. Designed to integrate with the RM/8000M family, the QM/8020/61/160 simplifies part stocking and procurement by aligning with existing mounting patterns. The result is faster installation, easier spare-part management, and improved uptime since maintenance teams deal with a familiar component family rather than a mix of bespoke parts. Material and finish choices in a guide block of this class are chosen to tolerate typical factory environments. Providing reliable guidance in pneumatic systems helps ensure consistent force transmission and reduces the risk of misalignment-driven faults in production tooling. From an ROI perspective, the combination of precise motion, low wear, and straightforward installation supports higher line productivity and reduced energy use per cycle. For engineers evaluating automation upgrades, the QM/8020/61/160 offers a proven path to dependable performance without extensive rework of existing RM/8000M installations.

Get a Quick Quote for a Norgren QM/8020/61/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/160?

Enquire Now

FAQs

The QM/8020/61/160 is designed to work with Norgren RM/8000M assemblies, sharing the same 20 mm bore geometry and 160 mm stroke. This alignment simplifies hardware selection and minimizes custom adapters, helping technicians complete installs quickly while ensuring repeatable guided motion across varied automation cells.

The 20 mm bore yields steady piston force suitable for moderate loads, while the 160 mm stroke defines the travel limit, enabling consistent extension in compact spaces. In automation lines, this translates to repeatable positioning, predictable cycle timing, and reduced variation in end positions across repeated operations.

The guide block provides precise guided motion and stable travel, which supports reliable high-speed performance. Dynamic loads and vibration must be considered, but when paired with RM/8000M and properly mounted, it can sustain rapid cycling with improved alignment. Always validate through application-specific testing and load calculations for your exact line requirements.

The data set does not specify certifications for QM/8020/61/160. In practice, Norgren components for control systems commonly pursue CE marking for safety and EMC compliance, with IP-rated variants for challenging environments. Always verify the exact certification status on the datasheet or with the supplier before use in regulated applications.

By providing a stable guide path and reducing misalignment, wear is minimized and uptime increases, lowering maintenance costs over the life of the automation line. The straightforward RM/8000M compatibility also reduces spare-parts inventory, improving total cost of ownership and shortening project payback time.