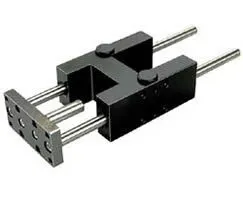

Norgren QM/8020/61/200 Guide Block - 20 mm Bore

Part Number: QM/8020/61/200

Quick Summary

QM/8020/61/200 guide block provides precise linear guidance for RM/8000M systems in automated manufacturing lines. Engineers often struggle with misalignment and downtime during high-speed cycles, making reliable guidance essential. While the data here doesn't list certification details, industry standards for automation components typically emphasize CE compliance and rugged protection against dust and moisture. This solution supports tighter installation tolerances, repeatable travel, and compatible mounting patterns, helping reduce scrap, downtime, and service costs. By aligning with RM/8000M, you gain simpler spare-part planning across the automation line. Secondary keywords include pneumatic guide block, 20 mm cylinder components, and Norgren compatibility, all contributing to faster deployment and consistent performance.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature: 20 mm bore and 200 mm stroke provide a compact yet capable travel envelope, enabling high-speed, repeatable motion. Business Impact: Reduces footprint while increasing reach within installation constraints, improving throughput in packaging and assembly lines. Application: Suitable for 20 mm bore pneumatic cylinder configurations across RM/8000M compatible systems. Paragraph 2: Feature: RM/8000M compatibility and standard mounting patterns simplify integration, lowering installation time and spare parts complexity. Business Impact: Faster commissioning, fewer adapters, and easier retrofits across existing Norgren portfolios. Application: Ideal for retrofits and new automation lines that require reliable alignment and quick setup. Paragraph 3: Feature: Brand reliability with IMI Norgren lineage enhances component availability and service support. Business Impact: Lower total cost of ownership through readily accessible spare parts and established service networks. Application: Widely adopted in industrial automation and control systems. Paragraph 4: Feature: Tight tolerances and straightforward alignment reduce maintenance frequency and risk of drift. Business Impact: More predictable performance and longer intervals between servicing. Application: Beneficial for high-cycle applications such as pick-and-place and material handling. Paragraph 5: Feature: Design supports clean air routing and minimal dynamic friction, contributing to energy efficiency. Business Impact: Reduced energy use and cooler operation under continuous duty. Application: Particularly impactful in high-throughput lines requiring consistent motion control. Paragraph 6: Industry context notes confirm this guide block as a backbone component for repeatable automation; using it across lines supports standardization, faster training, and safer, more reliable operation.

Get a Quick Quote for a Norgren QM/8020/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/200?

Enquire Now

FAQs

To install, align the guide block with the RM/8000M actuator mounting pattern, insert fasteners in the standard 4-bolt pattern, and secure per your machine’s torque requirements. Verify 20 mm bore alignment and confirm 200 mm stroke travel without binding. Use appropriate seals and lubrication to ensure smooth, repeatable motion and minimize install-time variability.

A 20 mm bore defines the piston diameter and related force capabilities, while a 200 mm stroke provides the travel distance required for typical pick-and-place or part-transfer tasks. Together, they support stable, repeatable cycles with predictable acceleration and deceleration, contributing to faster throughput and tighter process control in automated lines.

Yes, the QM/8020/61/200 guide block is well-suited for packaging, assembly, and transfer operations that demand precise guidance and reliable motion. Its 20 mm bore and 200 mm stroke accommodate compact layouts while maintaining repeatability, making it a practical choice for high-volume pick-and-place and material handling within automation systems.

Certification details are not listed in the provided data. In automation components, typical considerations include CE compliance and IP-rated protection depending on the installation environment. Check your project requirements and consult the supplier for exact certification documentation and environmental ratings applicable to your application.

The guide block offers long service life with readily available spare parts from Norgren, reducing downtime and maintenance costs. Standardized components across lines simplify stocking and training, delivering faster deployment and lower total cost of ownership through predictable performance and easier retrofits or expansions.