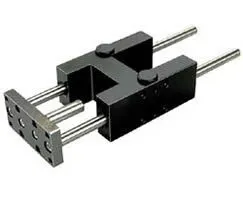

Norgren QM/8020/61/400 Guide Block - 20 mm bore

Part Number: QM/8020/61/400

Quick Summary

QM/8020/61/400 guide block provides precise linear guidance for RM/8000M pneumatic systems used in automation and packaging lines. Engineers often face misalignment, wear, and downtime when configuring long-stroke actuators without a robust guide block. In practice, industry standards such as CE compliance and IP ratings support safe operation in harsh environments, while SIL considerations inform safety-critical installations. This solution delivers reliable alignment and repeatable stroke with straightforward installation, helping you reduce setup time and maintenance costs. The 20 mm bore and 400 mm stroke combine to maximize controllability, while compatibility with Norgren RM modules delivers seamless integration and predictable performance for higher productivity.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature: The QM/8020/61/400 guide block pairs a compact 20 mm bore with a 400 mm stroke to deliver precise linear guidance in tight spaces around RM/8000M actuators, reducing misalignment during rapid cycling. This combination minimizes side loads, reduces wear, and maintains tight tolerances across multiple cycles, translating into higher repeatability on high-demand automation tasks. In practical applications such as packaging, assembly, and pick-and-place lines, the improved guidance supports consistent positioning, lowers scrap, and reduces reworks over a production shift. Compatibility with RM/8000M modules means installers can drop the block into existing systems with minimal alignment fiddling, quick mounting, fewer shim requirements, and predictable interface patterns that speed up commissioning. This approach preserves design margins for future line upgrades and reduces engineering effort during integration. The result is faster time-to-line, lower project costs, and greater confidence for system integrators and end users deploying multi-site automation. Quality and reliability come from IMI Norgren branding, signaling durable materials and tight manufacturing tolerances that resist wear in vibration-heavy environments. Expect consistent performance across shifts with minimal slack or backlash, even under temperature variation and dust exposure common on factory floors. That reliability supports tighter process control and higher-quality output in precision assembly and packaging operations. Maintenance and installation efficiency are reinforced by the guide block's streamlined design, reducing mounting complexity and oversights, enabling faster replacement cycles and simpler spare-part planning. Standardized mounting patterns minimize the need for custom adapters, lowering inventory and simplifying training for maintenance staff. Together with predictable wear life, this reduces downtime and extends overall equipment effectiveness in continuous production lines. Performance continuity is supported by the fixed 400 mm stroke, ensuring uniform motion profiles across cycles and stable cycle times for predictable throughput in high-demand environments. Paired with RM components, this guide block helps maintain tight tolerances, reduces variance in part placement, and contributes to better overall line efficiency. In dynamic applications such as pick-and-place and high-speed boxing lines, the combination delivers repeatable results with less operator intervention.

Get a Quick Quote for a Norgren QM/8020/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/400?

Enquire Now

FAQs

To install, align the guide block with the RM/8000M actuator housing using the standardized mounting pattern. Secure with appropriate fasteners, verify vertical and axial alignment, and confirm stroke travel without binding. Use the existing mounting holes to avoid adapters, check for smooth travel along the 400 mm stroke, and perform a brief functional test at low speed before full production.

Key specs include a 20 mm cylinder bore and a 400 mm stroke. The block is branded IMI Norgren and designed to integrate with RM/8000M modules, providing reliable linear guidance and repeatable motion essential for high-cycle automation tasks such as packaging and assembly.

Yes. The combination of a 20 mm bore and 400 mm stroke within the guide block supports precise, repeatable positioning needed in packaging and assembly lines, helping reduce scrap and misplacement while improving overall line efficiency when used with RM/8000M actuators.

The provided data does not list specific certifications. For regulatory compliance, consult the official datasheet or contact Norgren customer support to confirm CE marking, IP ratings, and any SIL-related considerations relevant to your safety-critical applications.

The guide block is designed for straightforward installation and durable operation, reducing commissioning time and downtime. With standardized mounting and reliable PM wear characteristics, total cost of ownership is lowered through fewer spare parts, easier replacements, and improved line uptime, contributing to a favorable return on investment in automated lines.