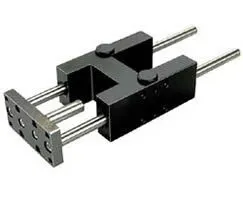

Norgren QM/8020/61/50 Guide Block - 20 mm Bore

Part Number: QM/8020/61/50

Quick Summary

The QM/8020/61/50 guide block from Norgren delivers precise linear guidance for RM/8000M pneumatic systems in automation environments. Engineers often struggle with misalignment and wear in compact guide hardware, which slows cycles and increases maintenance costs. This model features a CE-compliant design and rugged construction, with a 20 mm bore and 50 mm stroke that are well-suited to demanding applications. Its compatibility with RM/8000M assemblies and Norgren's 20 mm bore family supports streamlined procurement and spare-parts availability. For procurement and maintenance teams, this combination helps reduce downtime, shorten changeovers, and improve overall line throughput.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature: 20 mm bore and 50 mm stroke provide precise, repeatable linear guidance. Business Impact: Enables consistent motion across cycles, reducing wear on mating components and lowering maintenance frequency. Application: Ideal for RM/8000M integration in automation cells and fixture slides. Feature: Compatibility with RM/8000M assemblies simplifies installation and minimizes the need for adapters. Business Impact: Speeds up commissioning, lowers total install time, and reduces risk of misalignment. Application: Quick retrofits in existing automation lines and new panel assemblies. Feature: Rugged, compact guide block design improves durability in harsh environments. Business Impact: Extends service life, cuts spare-parts inventory, and minimizes unscheduled downtime. Application: High-cycle manufacturing lines and material-handling stations. Feature: Easy mounting and alignment features streamline maintenance. Business Impact: Reduces changeover time and maintains consistent performance with minimal expert intervention. Application: Tight spaces in control panels and machinery frames. Feature: Optimized geometry supports cost-effective lifecycle management. Business Impact: Lower total cost of ownership while preserving precision and reliability. Application: Long-run production automation and standardization initiatives.

Get a Quick Quote for a Norgren QM/8020/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/50?

Enquire Now

FAQs

Begin by aligning the RM/8000M carriage with the guide rail slot, mount using the product's standard mounting holes, and torque the fasteners to the recommended values from the Norgren installation guide. Ensure the 20 mm bore aligns with the actuator shaft and that there is no binding during travel. Verify travel limits and re-check alignment after the first cycles to prevent wear and misalignment over time.

The key specifications are a 20 mm cylinder diameter and a 50 mm stroke. This configuration provides precise linear guidance suitable for RM/8000M systems, enabling repeatable motion with consistent travel. These dimensions support compact integration in automation panels and fixture slides while maintaining reliable performance under typical industrial loads.

Yes, the 20 mm bore and 50 mm stroke design supports consistent, repeatable motion essential for high-cycle environments. Its rugged build reduces wear on interacting components, which translates to longer service intervals and lower maintenance costs. For high-cycle lines, pairing this guide block with regular preventive maintenance maximizes uptime and line throughput.

The provided product data does not specify certifications. For verification of CE status, IP ratings, or SIL considerations, consult the official Norgren datasheet or contact the supplier. Certification details are typically documented in the manufacturer’s technical documentation and may vary by region.

Expected benefits include reduced downtime due to improved alignment and wear resistance, faster changeovers from streamlined mounting, and lower lifecycle costs from longer component life. In practice, teams see more consistent cycle times, easier maintenance, and fewer spare-part variations, all contributing to a favorable return on investment in automated production cells.