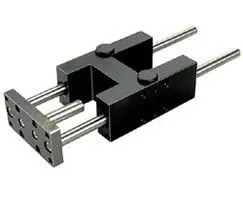

Norgren QM/8020/61/500 Guide Block - 20 mm bore

Part Number: QM/8020/61/500

Quick Summary

QM/8020/61/500 guide block provides precise linear guidance for pneumatic RM/8000M systems in automation applications. Engineers frequently wrestle with misalignment, wear, and inconsistent stroke that cause downtime and rework. In industrial settings, CE compliance and IP ratings are standard expectations, while SIL-rated variants support safety-critical control. This guide block enables reliable performance, straightforward retrofit, and dependable compatibility with RM/8000M—reducing maintenance events and improving throughput. For procurement and maintenance planning, these characteristics translate into faster commissioning and predictable performance across production lines.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature → 20 mm bore with tight tolerance provides improved engagement with the linear guides. Business Impact → Reduces runout and improves repeatability, lowering scrap and rework in fast-paced lines. Application → Ideal for high-precision pick-and-place, measurement fixtures, and compact automation modules in packaging and assembly. Feature → 500 mm stroke capability enables extended travel within a compact footprint. Business Impact → Supports longer travel per cycle without added support structures, boosting throughput. Application → Suitable for push-pull transfer tasks, clamp release in automation stations, and material handling. Feature → Direct RM/8000M compatibility and standardized mounting reduces integration complexity. Business Impact → Shortens commissioning time, lowers spare part variety, and reduces risk. Application → Retrofit of existing lines and new machine designs in OEM projects. Feature → Robust guide block construction and precision machining. Business Impact → Longer service life and lower maintenance downtime. Application → Harsh factory environments, temperature variations, and high-cycle operations. Feature → Simple installation and minimal lubrication requirements. Business Impact → Lower total cost of ownership due to reduced maintenance. Application → Service teams onboarding, installation in tight spaces, and field retrofits.

Get a Quick Quote for a Norgren QM/8020/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8020/61/500?

Enquire Now

FAQs

QM/8020/61/500 is designed to slot directly with Norgren RM/8000M actuators, sharing mounting standards and bore geometry. The 20 mm bore and 500 mm stroke deliver predictable guide performance, while straightforward clamping and alignment minimize commissioning time. Verify compatible end fittings and gaskets, and plan cable and tubing routes to avoid interference and vibration.

Key specs are a 20 mm bore and 500 mm stroke, paired with precise linear guidance for repeatable positioning. The guide block uses tight tolerances and robust surfaces to reduce play, lowering dynamic runout and wear. In typical automation lines, this improves cycle life, reduces rework, and enables sustained throughput over long production runs.

Yes. The 20 mm bore and 500 mm stroke support compact, high-precision guidance needed in packaging equipment and robotic fixtures. Its compatibility with RM/8000M simplifies retrofits on existing lines, while the durable construction withstands high-cycle operation. This makes it a solid choice for pick-and-place and handling tasks in modern manufacturing.

Industrial guide blocks in this class commonly align with CE requirements and IP-rated enclosures for hostile environments. For safety-critical applications, look for SIL-rated variants or safety-integrated solutions from the supplier. Always confirm with your supplier or distributor the exact certifications for the specific lot and configuration you intend to use.

Maintenance is typically minimal, focusing on routine inspection of mounting hardware and seals, with periodic lubrication per system standards. The robust machining and wear-resistant surfaces reduce downtime and replacement frequency, delivering lower maintenance costs and a favorable return on investment through higher uptime and consistent production throughput.