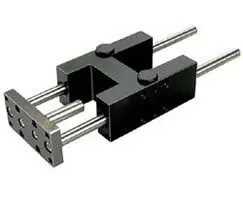

Norgren QM/8025/61/100 Guide Block - 25 mm Bore, 100 mm Stroke

Part Number: QM/8025/61/100

Quick Summary

The Norgren QM/8025/61/100 guide block provides precise linear guidance for RM/8000M pneumatic cylinders. Engineers often struggle with misalignment and wear in compact installations. Common certifications for automation components include CE marking for safety, IP ratings for environmental protection, and SIL-related standards for functional safety contexts, ensuring reliable operation in demanding environments. This solution reduces setup time and maintenance by delivering consistent stroke performance in 25 mm bore applications and integrates smoothly with other Norgren automation components. With robust compatibility and straightforward installation, it helps buyers improve downtime, extend service life, and achieve repeatable results in high-speed, high-precision automation lines.

Product Information

Cylinder diameter

25 mm

Brand

IMI Norgren

The QM/8025/61/100 guide block is built around a 25 mm bore that fits compact RM/8000M configurations, delivering precise linear guidance with minimal lateral play. This directly reduces misalignment and component wear, boosting positioning accuracy and repeatability on fast automation cycles. In practice, this means shorter setup times, fewer adjustments during changeovers, and lower maintenance costs in high-throughput lines. The 100 mm stroke expands reach within narrow spaces, enabling more versatile layouts without adding extra subassemblies, which translates to improved workspace efficiency and reduced part counts in your bill of materials. Designed to integrate with the Norgren automation ecosystem, installation is straightforward, support for spare parts is streamlined, and serviceability is enhanced across the lifecycle of RM/8000M systems. Industry context notes this design aligns well with packaging, assembly, and material-handling applications where space is constrained but precision matters. Expect better cycle consistency, reduced rework, and a clear path to scalable automation expands.

Get a Quick Quote for a Norgren QM/8025/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8025/61/100?

Enquire Now

FAQs

To install QM/8025/61/100 with RM/8000M, verify proper alignment between the cylinder axis and the guide block mounting surface, use the correct mounting hardware, and avoid over-tightening. Start with clean, lubricated interfaces and test travel early to confirm smooth motion. Keep the assembly free from debris to protect precision guidance over time.

With a 25 mm bore and 100 mm stroke, the unit supports compact, repeatable travel for high-speed placement tasks. The tight bore reduces lateral play, while the longer stroke enables extended reach without additional assemblies. This combination improves repeatability, minimizes cycle time, and reduces misfeeds and part downtime in packaging lines.

Certification specifics for this guide block are not listed in the provided data. In practice, verify CE compliance for safety systems and confirm IP protection level for your environment. For applications requiring SIL safety integrity, ensure the overall system architecture meets relevant standards. When in doubt, consult the supplier for exact certifications related to your risk assessment.

Regular inspection should focus on alignment, fasteners, and the guide surface wear. Schedule periodic checks aligned with production tempo to detect wear before it affects accuracy. Replace worn components promptly, and maintain clean lines to avoid debris ingress. Using a compatible lubrication schedule with RM/8000M keeps travel smooth and extends service life, reducing unplanned downtime.

Yes. By improving uptime, reducing rework, and enabling longer service life between replacements, the QM/8025/61/100 lowers total cost of ownership in high-volume lines. Its compatibility with existing Norgren parts minimizes spare parts variety and training needs, delivering faster ROI and steadier production throughput through predictable maintenance and streamlined replacement planning.