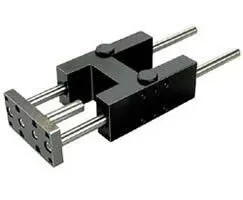

Norgren QM/8025/61/250 Guide Block - 25 mm Bore, 250 mm Stroke

Part Number: QM/8025/61/250

Quick Summary

Norgren QM/8025/61/250 guide block is a precision guiding component for RM/8000M cylinders used in automated manufacturing. Engineers often struggle with misalignment, wear, and downtime when using generic blocks that don’t suit high-load pneumatic systems. Certification notes: while specific certifications aren’t listed in the data, you’ll typically see CE-compliant variants and IP-rated protection in this class; confirm exact ratings with your Norgren distributor. For businesses, the block delivers durable alignment and repeatable motion, reducing maintenance cycles. Using it with RM/8000M cylinders, you gain reliable automation performance and clearer total-cost-of-ownership benefits, supporting lean manufacturing and predictable throughput.

Product Information

Cylinder diameter

25 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 25 mm bore and 250 mm stroke provide compact, stable guidance for RM/8000M cylinders, reducing side loads and improving straight-line motion across thousands of cycles. The result is higher positional repeatability, lower wear, and longer service intervals—translating to reduced maintenance costs and less downtime in automated lines. In practice, this combination suits packaging lines, automotive assembly cells, and conveyor systems where precise guided motion is paramount. Additionally, the compact form helps fit into tight machinery bays without sacrificing stroke length. Feature → Business Impact → Application: As a dedicated guide block, it minimizes misalignment risk during dynamic motion, which directly reduces scrapped parts and sensor misreads. The improved rigidity also protects ancillary components, extending actuator life and stabilizing feedback signals. Applications include rack-and-pinion conveyors, palletizing cells, and quality-control stations where repeatable positioning is critical. This stability also supports accurate metrology and inspection tasks. Feature → Business Impact → Application: Compatibility with RM/8000M mounting patterns and common pneumatic interfaces simplifies retrofit projects, minimizes installation time, and lowers training requirements for maintenance teams. End-users can source spares more easily and achieve faster ROI thanks to reduced downtime and increased equipment uptime. The design also supports modular automation architectures and future expansion. Feature → Business Impact → Application: In modern automation, integrated guide blocks like QM/8025/61/250 enable better alignment with sensors and feedback loops, supporting lean operations and predictable maintenance planning. For engineers, the result is clearer procurement decisions, improved supplier collaboration, and lower total cost of ownership over cylinder assets. This configuration also aids scalable line design and easier line upgrades.

Get a Quick Quote for a Norgren QM/8025/61/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8025/61/250?

Enquire Now

FAQs

Installation begins with confirming mounting compatibility between the guide block and the RM/8000M cylinder. Align the block along the cylinder axis, secure with the standard fasteners specified by Norgren, and verify the travel path is free of obstructions. After mounting, perform a light-cycle test to confirm smooth, straight motion and re-torque fasteners as needed. Routine checks should include bearing and guide rail inspection and lubrication per maintenance guidelines.

The unit features a 25 mm bore and a 250 mm stroke, delivering compact yet robust linear guidance for RM/8000M configurations. The bore supports adequate load distribution while the extended stroke provides necessary travel for typical automation tasks. Together, these specs improve repeatability, reduce side loads, and support stable sensor feedback, which translates into consistent part placement and cycle timing in high-throughput lines.

Yes, when used with RM/8000M cylinders, the QM/8025/61/250 guide block offers improved alignment and reduced wear in high-cycle environments. Its dedicated design minimizes misalignment and stabilizes motion, helping maintain tight tolerances during rapid pick-and-place or packing operations. For best results, pair it with appropriate lubrication schedules and regular alignment checks aligned to your production rate.

Certification details are not specified in the provided data. In practice, verify with the supplier or Norgren catalog for CE marking, IP ratings, and any SIL/functional safety considerations relevant to your application. When sourcing, request documentation that confirms the exact certifications for your intended configuration and operating environment.

To maximize ROI, implement a preventive maintenance plan that includes regular inspection of the guide block alignment, bearing surfaces, and fastener torque. Apply appropriate lubrication at recommended intervals, and track wear indicators on the RM/8000M assembly. Documented maintenance reduces unplanned downtime, extends life, and improves overall line throughput and reliability.