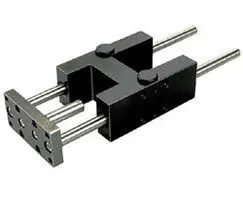

Norgren QM/8025/61/320 Guide Block - 320 mm Stroke

Part Number: QM/8025/61/320

Quick Summary

The QM/8025/61/320 guide block provides precise linear guidance for RM/8000M cylinders in automation systems. Engineers often contend with misalignment, stick-slip, and unnecessary wear in compact guides, which drives downtime and maintenance costs. This product alignment supports common standards—CE compliance in many regions, reliable protective features, and compatibility with standard Norgren fittings—ensuring safer, predictable operation. By delivering stable guiding performance, it reduces setup time and enables higher cycle accuracy. The block's 25 mm bore and 320 mm stroke compatibility align with typical RM/8000M configurations, empowering procurement to standardize components. This translates to improved uptime, reduced spare-part complexity, and a more streamlined supply chain for industrial automation projects.

Product Information

Cylinder diameter

25 mm

Brand

IMI Norgren

Feature: The QM/8025/61/320 guide block delivers precise linear guidance for RM/8000M actuators, featuring a 25 mm bore and 320 mm stroke that aligns with standard pneumatic cylinder footprints. Business impact: tighter guidance reduces lateral loads and wear, resulting in longer life for guides and cylinders and lower seal leakage over time. Application: ideal for high-repeatability tasks in packaging, robotic tooling, and conveyor systems where consistent stroke and positional accuracy are essential. Feature: Direct mounting compatibility with Norgren RM-series hardware simplifies integration in existing lines. Business impact: engineers save design time, eliminate custom brackets, and accelerate commissioning. Application: retrofits and new lines alike benefit from predictable mounting holes and standardized fasteners across automation cells. Feature: Robust construction tolerates dust, vibration, and temperature fluctuations commonly found on factory floors. Business impact: reduces unplanned downtime and maintenance visits, improving overall equipment effectiveness. Application: suitable for dusty conveyors, paint lines, and packaging environments when used with appropriate seals and guards. Feature: Standardized part family supports streamlined procurement and spare-parts inventory. Business impact: lowers total cost of ownership by reducing SKUs and simplifying vendor management. Application: procurement teams can consolidate orders for RM/8000M-compatible Norgren components and reduce lead times.

Get a Quick Quote for a Norgren QM/8025/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8025/61/320?

Enquire Now

FAQs

To install, align the guide block with the RM/8000M mounting pattern, secure using the standard fasteners defined for Norgren RM-series hardware, and confirm the bore alignment is concentric with the piston rod. Verify that the mounting surfaces are clean and free of debris, then cycle the actuator to confirm smooth, guided motion. Proper torque and alignment ensure reliable performance and minimal lateral load.

Its 25 mm bore and 320 mm stroke provide a compact yet robust guidance solution that minimizes misalignment and stick-slip, improving repeatability at high cycle rates. The direct-mount design reduces setup time, while the tight guiding tolerances help maintain consistent positional accuracy across rapid cycles, lowering scrap and downtime in packaging environments.

Yes. The guide block is designed to integrate with RM-series hardware and standard Norgren fittings, streamlining upgrades and retrofits. This compatibility reduces engineering effort, simplifies spare-parts planning, and supports a modular approach to expanding automation cells without unique or custom components.

The QM/8025/61/320 aligns with common industrial expectations such as CE compliance in applicable regions and compatibility with standard industrial fittings. Always verify regional regulatory requirements for your installation and confirm that the complete system—including guides, actuators, and mounting hardware—meets your site’s safety and quality standards.

By delivering precise alignment, reduced wear, and faster installation, the QM/8025/61/320 guide block supports higher line uptime and lower maintenance costs. Standardized components reduce spare-parts complexity and procurement lead times, contributing to lower total cost of ownership and a quicker payback on automation projects.