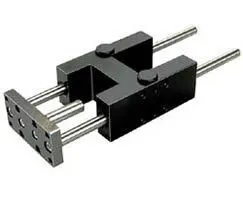

Norgren QM/8025/61/50 Guide Block - 25 mm Bore

Part Number: QM/8025/61/50

Quick Summary

QM/8025/61/50 guide block provides precise guidance for RM/8000M cylinders in compact automation lines. Installation teams often battle misalignment and sticky components that drive cycle times and increase wear. While CE marking and IP-rated enclosures are standard in industrial environments, SIL considerations are addressed at the overall control system level to maintain safety and reliability. In practice, this guide block integrates with Norgren’s RM/8000M ecosystem, simplifying procurement and reducing mounting complexity. By delivering reliable alignment and robust construction, it helps manufacturers achieve higher uptime and predictable performance across automated production lines. This aligns with lean manufacturing goals and supports faster changeovers.

Product Information

Cylinder diameter

25 mm

Brand

IMI Norgren

The 25 mm bore with a 50 mm stroke provides reliable guidance for RM/8000M cylinders, minimizing side loads and ensuring stable motion through the full stroke. Business impact: higher positioning accuracy, reduced wear on seals and sliders, and lower cycle variability. Application: ideal for precision pick-and-place, robotic integration, and short-stroke indexing in automotive, packaging, and medical device manufacturing. Compatibility and installation are simplified by standard mounting patterns and direct interfacing with the RM/8000M family. Business impact: faster line integration, shorter downtime during refits, and fewer commissioning surprises. Application: retrofits or new lines where tight timelines demand plug-and-play alignment with minimal modification. Durability and consistency are reinforced by the guide block design, which resists misalignment-induced wear and maintains alignment under vibration and dust exposure typical of shop floors. Business impact: extended service life and reduced maintenance costs; predictable performance in harsh environments. Application: continuous manufacturing and high-cycle environments. BOM complexity is reduced because the QM/8025/61/50 is part of a modular ecosystem with common 25 mm bore components. Business impact: lower total cost of ownership and easier spare-part provisioning. Application: multi-vendor automation projects where standardization matters. Industry practitioners often worry about installation challenges; this block’s clear mounting references and compatibility with existing Norgren line components address that by enabling straightforward alignment checks and faster changeovers.

Get a Quick Quote for a Norgren QM/8025/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8025/61/50?

Enquire Now

FAQs

The QM/8025/61/50 is designed for RM/8000M pneumatic cylinders with a 25 mm bore and a 50 mm stroke. It utilizes standard mounting patterns within the RM/8000M family, enabling plug-and-play alignment and straightforward retrofits. Ensure correct mounting hardware is used and verify spacing to match your cylinder end caps and guides for optimal performance.

A 25 mm bore provides a compact yet rigid guide interface, improving lateral stability and reducing side loads during motion. This translates to more repeatable positioning, smoother operation, and longer seal and slider life, especially in high-cycle or high-speed applications such as packaging and assembly lines.

Yes. The combination of 25 mm bore and 50 mm stroke is well-suited for precise guide duties in packaging, pick-and-place, and small-part handling. Its compatibility with RM/8000M cylinders helps streamline line design, minimize insertion forces during assembly, and support reliable, repeatable campaigns with reduced downtime.

In practice, guide blocks like this are integrated into CE-compliant control systems and paired with IP-rated enclosures as part of the overall machine safety strategy. SIL considerations are addressed at the system level, not by the guide block alone, so ensure your complete automation stack meets applicable safety and regulatory requirements.

Adopt a regular inspection schedule to verify alignment and mounting integrity, especially after changeovers or high-cycle runs. Replace worn fasteners and inspect the guides for wear patterns; keeping spare mounting hardware and guides on hand minimizes downtime. The block’s modular design and compatibility with standard RM/8000M parts help reduce total cost of ownership through easier part sourcing and faster maintenance.