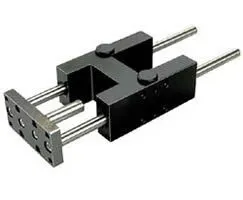

Norgren QM/8025/61/500 Guide block - 25 mm bore

Part Number: QM/8025/61/500

Quick Summary

The QM/8025/61/500 guide block provides precise linear guidance for RM/8000M pneumatic cylinders in automation. Misalignment, wear, and mounting complexity often drive downtime and inconsistent motion. In regulated environments, CE conformity, IP protection, and SIL considerations are common expectations for automation components. This Norgren block delivers robust compatibility with RM/8000M assemblies, reducing commissioning time and extending service life, while enabling repeatable motion essential for high-volume manufacturing. In addition, its compact form and standard mounting patterns simplify retrofit projects and spare parts planning.

Product Information

Cylinder diameter

25 mm

Brand

IMI Norgren

Feature: The 25 mm bore and 500 mm stroke of the QM/8025/61/500 provide a precise, linear guidance path for RM/8000M cylinders. Business Impact: This geometry reduces side loads and motion jitter, delivering repeatable cycles and tighter process control. Application: Ideal for high-volume packaging, automated assembly, and material handling lines where consistent positioning directly drives throughput and quality. Feature: Mounting compatibility with the RM family enables straightforward installation. Business Impact: Reduces commissioning time and risk of misalignment. Application: OEM retrofits and new lines that reuse existing RM/8000M components. Feature: Durable guide surfaces and low-friction guidance. Business Impact: Extends service life, reduces wear, and lowers maintenance frequency. Application: Harsh factory environments or dusty lines where reliability matters. Feature: Easy serviceability and field replaceability. Business Impact: Minimizes downtime during maintenance windows and speeds component swaps. Application: Scheduled maintenance in continuous production environments. Feature: Clear documentation and standard mounting patterns. Business Impact: Improves traceability, simplifies compliance, and enhances supplier consistency. Application: System integrators and maintenance teams seeking reliable, repeatable components.

Get a Quick Quote for a Norgren QM/8025/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/8025/61/500?

Enquire Now

FAQs

Yes. The QM/8025/61/500 guide block is designed to pair with RM/8000M cylinders and follows standard Norgren mounting patterns. During installation, align precisely with the cylinder axis, fasten with the recommended torque, and use compatible fasteners and end fittings. This alignment discipline minimizes side loads and improves repeatability across automated cells.

Core specs include a 25 mm bore and a 500 mm stroke, with standard Norgren RM compatibility. Verify mounting orientation, end-cap dimensions, and installation clearances to ensure smooth integration. The guide block delivers repeatable linear guidance for packaging, pick-and-place, and automation tasks, enabling predictable cycle times and reduced positional drift in demanding environments.

Yes. The block's low-friction guidance and robust design tolerate rapid cycles while maintaining accuracy. To maximize performance, ensure proper lubrication, precise alignment, and correct mounting torque. Consider routine wear-part inspection and timely replacements; protect against dust ingress in harsh lines to sustain reliability at high speeds.

Check for CE conformity and IP rating appropriate to your environment; SIL compliance may be required for safety-critical systems. Always verify supplier documentation and match the product specifications to your facility’s regulatory and safety requirements to ensure compliant integration.

Plan regular inspections of guides and seals, maintain proper lubrication, and confirm mounting fasteners remain torqued. By reducing downtime, preventing misalignment, and extending component life, the QM/8025/61/500 delivers lower total cost of ownership and higher uptime, contributing to improved line throughput and return on investment for automation projects.