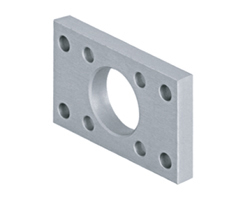

Norgren QM/90020/22 Front/Rear Flange Mounting 20mm bore

Part Number: QM/90020/22

Quick Summary

QM/90020/22 is a 20 mm bore flange-mounted actuator for compact pneumatic control in automation systems. Engineers often struggle with mounting flexibility and precise alignment in tight spaces. Certification details are not listed here; in the Norgren family, CE marking and robust IP-rated variants are common, with SIL suitability available on select configurations. This design supports quick installation and straightforward retrofits, delivering reliable actuation and repeatable performance while reducing downtime and maintenance costs. For procurement and engineering teams, the 20 mm bore, front/rear flange mounting and proven brand reliability translate into smoother integration and longer service life across automated lines.

Product Information

Cylinder diameter

20 mm

Brand

IMI Norgren

Feature: 20 mm bore flange-mounted cylinder. Business Impact: Enables a compact footprint and versatile installation in crowded machine layouts, reducing overall system size and enabling easier maintenance access. Application: Small transport and pick-and-place modules where space is at a premium and precision is essential. Feature: Front and rear mounting compatibility. Business Impact: Provides installation flexibility to optimize stroke direction and alignment, reducing rework during line upgrades. Application: Conveyor gates, rotary indexes, and modular automation stations. Feature: IMI Norgren brand reliability. Business Impact: Delivers consistent actuation performance, lower maintenance intervals, and extended service life in demanding factory environments. Application: General automation, packaging lines, and assembly cells. Feature: Compatibility with standard manifolds and end blocks. Business Impact: Cuts installation time, minimizes leak paths, and simplifies spare-part management. Application: Retrofit projects and new line implementation. Feature: Space-saving design with straightforward integration. Business Impact: Improves line density and reduces total cost of ownership by lowering installation labor and wiring requirements. Application: Robotic pick-and-place, small-assembly fixtures, and control cabinet-limited layouts. Long-tail keywords: 20 mm bore pneumatic cylinder, flange-mounted actuator, front rear mounting cylinder, IMI Norgren cylinder, compact pneumatic cylinder, industrial automation actuator, installation-friendly mounting, standard manifold compatibility.

Get a Quick Quote for a Norgren QM/90020/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/90020/22?

Enquire Now

FAQs

QM/90020/22 uses a 20 mm bore with flange mounting designed for common industrial mounting schemes. It is compatible with typical end blocks and manifolds used in automation lines, enabling straightforward retrofits and simplified spare-part planning. Always verify exact hole spacing and mounting alignment against your existing fixture to ensure a seamless fit.

The product is specified as a 20 mm bore flange-mounted actuator. While the data provided does not list stroke length, force, or operating pressure, you can expect standard 20 mm bore cylinders to cover light-to-medium actuation duties in automated lines. Confirm stroke, operating pressure range, and rod end configurations with the supplier prior to procurement.

Certification and material suitability for hygienic or food-grade applications are not specified in the data. For such environments, check enclosure IP rating, surface finishes, and material approvals with the supplier, and consider dedicated hygienic versions if required. Compatibility with cleanroom or washdown cycles should be verified before deployment.

Certification details are not listed in the provided data. In general, Norgren components often carry CE markings and IP ratings; SIL suitability can be available on select configurations. Contact the supplier or Norgren documentation to confirm current certifications for your region and application, especially for safety-critical or regulated environments.

Flange-mounted 20 mm bore cylinders reduce installation time by simplifying mounting and alignment, lowering commissioning effort, and enabling easy retrofits. Their compact footprint frees space for other components, while compatibility with standard manifolds reduces spare parts and wiring complexity. The result is shorter downtime during changeovers and improved line uptime in automation projects.