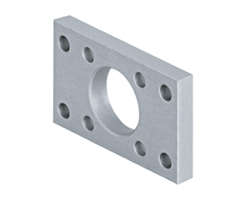

Norgren QM/90040/22 Pneumatic Cylinder - 40 mm Bore

Part Number: QM/90040/22

Quick Summary

QM/90040/22 is a compact pneumatic cylinder delivering precise linear motion for automation and control systems. Engineers often grapple with mounting versatility and reliable performance in compact 40 mm bore cylinders. For reliability and safety, look for CE compliance and standard IP-rated protection; verify the exact certification scope in the supplier documentation. Procurement teams benefit from standard bore size and flange mounting compatibility, which simplifies stocking, integration with existing manifolds, and reduces commissioning time. Operational efficiency improves through clean, consistent actuation and predictable response under typical factory air quality. By choosing a trusted brand like Norgren, you gain long-term support, traceable components, and better total cost of ownership on automated lines.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

The QM/90040/22 uses a 40 mm bore pneumatic cylinder with a compact footprint designed to maximize actuator stroke in tight enclosures and crowded machinery bays. The 40 mm bore delivers consistent force for medium-load actuation in automation lines, while the compact length reduces envelope height. In high-density layouts, the smaller footprint translates to more stations per line and easier service access, improving overall line throughput. Front and rear flange mounting provides flexible installation options for conveyors, pick-and-place cells, and packaging equipment. This mounting versatility simplifies retrofits and changes in line configuration, reducing project lead times and field engineering effort. When space is at a premium, flange-mounted cylinders minimize interference with sensors and other actuators while maintaining alignment integrity. As part of the IMI Norgren family, the QM/90040/22 benefits from established component standards, readily available spare parts, and a global support network. The design emphasizes repeatable performance across cycles, with proven seal configurations and consistent pneumatic interfaces. That reliability lowers maintenance downtime and streamlines procurement in multi-site manufacturing environments. The cylinder supports standard pneumatic interfaces and is compatible with common control valves, manifolds, and lubricated or non-lubricated air systems. Its simple installation reduces the risk of misassembly and the need for specialty adapters. Operators can integrate the unit quickly with existing compressed air systems, minimizing commissioning risk. Maintenance benefits stem from modular seals and straightforward diagnostics; standardized parts make replacement straightforward and inexpensive. In high-cycle automation, longer service intervals translate into measurable cost savings and reduced downtime. Overall, the QM/90040/22 helps improve line uptime, throughput, and total cost of ownership. Note this content reflects the product data's 40 mm bore and flange mounting features; always consult the official datasheet for exact stroke, speed, operating pressure, and environmental ratings.

Get a Quick Quote for a Norgren QM/90040/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/90040/22?

Enquire Now

FAQs

Install QM/90040/22 by aligning the mounting holes on the front or rear flange with the machine frame, inserting the appropriate bolts, and torquing to the design specification. Ensure the actuator is oriented for a clean air inlet and that the mounting surface is flat and true to avoid bind or misalignment. Verify that the connection interfaces mate with existing manifolds and valves to maintain consistent stroke and sealing performance.

QM/90040/22 features a 40 mm bore for compact yet capable actuation and is designed for precise linear movement in automation lines. The data highlights the flange mounting option and IMI Norgren build, but stroke, speed, and maximum operating pressure should be confirmed on the official datasheet. It integrates with standard pneumatic manifolds and control valves for straightforward commissioning.

Yes. The 40 mm bore and flange mounting provide a compact footprint and flexible installation, which supports tight packaging environments and fast actuation cycles common in pick-and-place cells. Ensure the stroke and cycle rate align with your payload and speed requirements, and pair the cylinder with compatible sensors and valves to optimize repeatability and throughput.

The provided product data does not list specific certifications. For regulatory compliance, look for CE marking and IP protection ratings in the supplier documentation; verify safety certificates if your application operates in hazardous or safety-critical environments. Always request the official datasheet and declaration of conformity to ensure regional requirements are met.

Maintenance prospects center on standard seals and modular design that simplify replacement and diagnostics. In high-cycle automation, longer service intervals mean reduced downtime and lower maintenance costs. ROI arises from improved line uptime, faster commissioning, and straightforward spare parts sourcing thanks to common bore size and mounting interfaces.