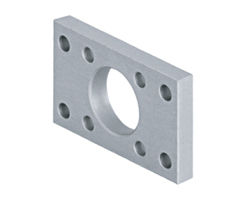

Norgren QM/90080/22 Pneumatic Cylinder - Front/Rear Flange Mounting 80mm Bore

Part Number: QM/90080/22

Quick Summary

Norgren QM/90080/22 is a compact pneumatic cylinder for automated control systems in packaging and assembly. Engineers often wrestle with mounting flexibility and consistent actuation in space-constrained lines, and this model addresses those pain points. Standard industry certifications such as CE compliance and SIL readiness, along with IP-rated variants, are important considerations for actuation hardware in regulated or harsh environments. By leveraging front/rear flange mounting and a proven 80 mm bore, it reduces installation time, simplifies maintenance, and lowers total cost of ownership across OEM deployments while improving uptime and repeatable performance in automation tasks.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: Front/Rear flange mounting provides mounting versatility across machinery frames. Business Impact: Reduces custom fabrication and speeds system integration, minimizing downtime during line changes. Application: Ideal for conveyors, pick-and-place stations, and machine tool setups. Feature: 80 mm cylinder diameter delivers robust thrust for reliable actuation in standard automation tasks. Business Impact: Enables consistent motion control and repeatable cycles, increasing throughput and product quality. Application: Clamp actuation, part ejection, and stack transfers in compact layouts. Feature: Compatibility with standard Norgren fittings and manifolds simplifies retrofits and spares management. Business Impact: Lowers maintenance costs and stock-keeping requirements, improving uptime. Application: Retrofit projects and scalable automation architectures. Feature: Quick alignment and installation with flange mounting reduces changeover time and setup complexity. Business Impact: Shortens commissioning, lowers labor costs, and enhances line flexibility. Application: Rapidly reconfigured packaging lines and configurable automation cells. Feature: Solid build and sealing for longevity in industrial environments. Business Impact: Extends service intervals and lowers lifecycle costs, supporting longer uptime in dirty or demanding settings. Application: Hazardous or challenging facilities where reliability is critical.

Get a Quick Quote for a Norgren QM/90080/22

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QM/90080/22?

Enquire Now

FAQs

QM/90080/22 supports front and rear flange mounting, which provides versatile alignment on machine frames and automation cells. The flange pattern aligns with standard 80 mm bore cylinders, enabling quick bolt-in installations and straightforward retrofits, reducing commissioning time and specialist setup requirements.

The cylinder features an 80 mm bore (diameter) with the QM/90080/22 designation, branded under Norgren. The flange-mount configuration simplifies mounting and alignment on compact automation lines, and it integrates with standard Norgren fittings and manifolds for reliable actuation.

Yes. The QM/90080/22 is designed for automated control systems, with mounting versatility and a robust 80 mm bore suitable for medium-duty actuation in packaging, assembly, and material handling applications. Its modular mounting and compatibility with existing Norgren components support rapid deployment on production lines.

Check for CE compliance and verify any region-specific certifications such as IP ratings and SIL readiness based on your application and location. Certification availability can vary by configuration, so consult the official datasheet or supplier to confirm the exact certifications for your chosen setup.

Plan for seal maintenance and routine inspection of mounting interfaces and fittings. Source OEM spare parts and service kits when needed to preserve performance. The 80 mm bore configuration and flange mounting facilitate quick seal replacements and straightforward field servicing, helping minimize downtime and extend service intervals in continuous-operation environments.