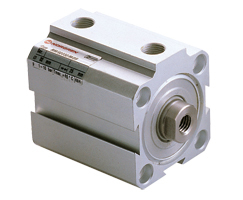

Norgren RM/92080/M/225 Pneumatic Cylinder - 80 mm Bore

Part Number: RM/92080/M/225

Quick Summary

The RM/92080/M/225 pneumatic cylinder is a compact double-acting actuator designed for precise linear motion in automation and packaging lines. When space is at a premium, its one-third shorter length compared with many ISO/VDMA models helps maintain reach without expanding the footprint, delivering efficient installations. Although the data sheet does not list CE or IP certifications, the unit uses a fully non-corrodible construction and a magnetic piston for versatile integration with sensing and control systems, with operating temperature -5 to 80 °C and operating pressure 1 to 10 bar. These characteristics support reliable performance in industrial automation, while the combination of corrosion resistance and magnetic sensing adds value for customers aiming to optimize maintenance schedules and system integration in tight spaces.

Product Information

Extended Description

RM/92080/M/225 Norgren: One third the basic length of a corresponding ISO/VDMA model | Low friction, long life seal design | Fully non-corrodible specification | Standard magnetic piston for full control system versatility

Medium

Compressed air

Operating Temperature

-5 ... 80 °C, 23 ... 176 °F

Operating Pressure

1 ... 10 bar, 14 ... 145 psi

Port Size

G1/4

Cylinder diameter

80 mm

Stroke Length

225 mm

Operation

Double acting

Cushioning

No cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

3016 N

Materials - Barrel

Anodised aluminium alloy

Materials - Piston Rod

Stainless steel (martensitic)

Range

RM/92000/M

Brand

IMI Norgren

Feature: 80 mm bore and 225 mm stroke deliver a compact envelope with extended travel. Business Impact: Enables longer stroke reach in restricted spaces, reducing the need for additional linkages or multiple actuators. Application: Pick-and-place and part-feed acts in small-format automation cells where space is at a premium. Feature: Low friction, long-life seals. Business Impact: Increases cycle life and reduces maintenance costs in high-duty installations. Application: Continuous operation lines in packaging, where uptime directly affects throughput. Feature: Fully non-corrodible construction. Business Impact: Improves durability in challenging environments, lowering replacement and downtime costs. Application: Washdown-ready or corrosive-part handling applications within food, beverage, or chemical processing. Feature: Magnetic piston. Business Impact: Facilitates straightforward integration with non-contact or contact sensing, simplifying control schemes and reducing installation time. Application: System with reed switches or magnetic sensors for precise position feedback. Feature: Materials - Barrel and Piston Rod (Anodised aluminium; Stainless steel). Business Impact: Combines lightweight strength with corrosion resistance for longer service life and easier maintenance. Application: General automation tasks across pneumatics & fluid systems, where durability matters. Feature: Port Size G1/4; Operating Pressure 1-10 bar. Business Impact: Aligns with standard plant air systems, simplifying plumbing and reducing installation cost. Application: Retrofit projects or new lines that rely on common pneumatic interfaces.

Get a Quick Quote for a Norgren RM/92080/M/225

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren RM/92080/M/225?

Enquire Now

FAQs

The RM/92080/M/225 uses standard G1/4 ports, which align with common Euro and North American manifolds. Ensure your air supply is clean and regulated between 1 and 10 bar, and mount using standard clevis or flange options to optimize alignment for the 225 mm stroke. Check available space to accommodate the 80 mm bore while maintaining smooth rod travel.

This cylinder operates from -5 to 80 °C and 14 to 145 psi (1 to 10 bar). This broad range makes it suitable for general factory environments and varying climatic conditions, supporting consistent performance in demanding automation tasks without frequent reconfiguration.

Yes, the RM/92080/M/225 features a magnetic piston. This enables straightforward integration with magnetic, reed, or proximity sensors for position feedback, reducing wiring complexity and enabling reliable closed-loop control in pick-and-place, clamping, or end-of-line operations.

The design uses a fully non-corrodible specification and stainless steel piston rod in a corrosion-resistant barrel, which improves longevity in challenging environments. While ideal for many washdown-ready applications, always verify material compatibility with the specific chemicals and cleaning agents used in your process.

The combination of low-friction seals, a long-lasting non-corrodible build, and a compact form factor reduces downtime and maintenance frequency. In high-cycle lines, this translates to higher throughput, longer service intervals, and a lower total cost of ownership due to fewer part replacements and less frequent calibration or sensor integration adjustments.