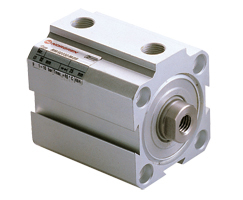

IMI Norgren RM/92080/M/255 Pneumatic Cylinder - Magnetic

Part Number: RM/92080/M/255

Quick Summary

Pneumatic Cylinder RM/92080/M/255 provides compact, double-acting actuation for automated assembly and material handling. Engineers face tight spaces, mounting challenges, and wear from long-stroke cylinders, so a shorter form factor can dramatically simplify integration. While specific certifications aren’t listed for this model, industry validation typically centers on CE compliance and rugged protection; the design features an anodised aluminium barrel, a martensitic stainless steel rod, and a magnetic piston to support reliable, long-life operation. This combination enables consistent, repeatable motion in demanding environments, with improved cycle times and reduced maintenance, translating to lower total cost of ownership. The cylinder also supports straightforward integration with control systems, contributing to overall equipment efficiency and uptime.

Product Information

Extended Description

RM/92080/M/255 Norgren: One third the basic length of a corresponding ISO/VDMA model | Low friction, long life seal design | Fully non-corrodible specification | Standard magnetic piston for full control system versatility

Medium

Compressed air

Operating Temperature

-5 ... 80 °C, 23 ... 176 °F

Operating Pressure

1 ... 10 bar, 14 ... 145 psi

Port Size

G1/4

Cylinder diameter

80 mm

Stroke Length

255 mm

Operation

Double acting

Cushioning

No cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

3016 N

Materials - Barrel

Anodised aluminium alloy

Materials - Piston Rod

Stainless steel (martensitic)

Range

RM/92000/M

Brand

IMI Norgren

Feature: 80 mm bore and 255 mm stroke offer substantial force within a compact footprint. Business Impact: Enables strong actuation in space-constrained machinery, reducing machine height and footprint without sacrificing performance. Application: Pick-and-place and transfer tasks on compact automated lines benefit from dependable stroke and force. Keyword: 80 mm bore pneumatic cylinder, compact actuator. Feature: One-third the basic length of a comparable ISO/VDMA model improves installability and serviceability. Business Impact: Streamlines enclosure design, lowers installation time, and simplifies retrofit projects, cutting total project cost. Application: Retrofit projects in packaging lines and assembly cells where space is at a premium. Keyword: compact pneumatic cylinder, space-saving actuator. Feature: Low friction, long-life seal design reduces wear and energy loss. Business Impact: Decreases maintenance intervals and ensures smoother cycling, boosting overall line efficiency. Application: High-cycle applications such as automated pick-and-place with frequent actuations. Keyword: low-friction seals, long-life cylinder. Feature: Fully non-corrodible specification with anodised barrel and martensitic stainless rod. Business Impact: Extends service life in challenging manufacturing environments, lowering replacement and downtime costs. Application: Food and beverage,/pharma-like environments with cleaning regimes or exposure to moisture. Keyword: corrosion-resistant pneumatic cylinder. Feature: Magnetic piston enables full control-system versatility and easy sensing integration. Business Impact: Simplifies position sensing and feedback loops, improving automation reliability. Application: Sensorized automation lines and PLC-driven sequences. Keyword: magnetic piston cylinder. Feature: Wide operating range and robust construction support versatile deployment. Business Impact: Accepts 1–10 bar supply and -5 to 80 °C ambient conditions, enabling use across multiple lines with a single part. Application: General automation and equipment tenders requiring flexible actuation. Keyword: double acting cylinder, variable pressure range. Each feature is designed to deliver measurable outcomes: higher throughput, reduced downtime, and smoother integration with existing pneumatic networks. The combination of durable materials, standard porting (G1/4), and a proven magnetic piston provides a reliable, field-friendly solution that aligns with industry best practices for industrial automation and material handling.

Get a Quick Quote for a Norgren RM/92080/M/255

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren RM/92080/M/255?

Enquire Now

FAQs

For proper installation, ensure mounting compatibility with standard cylinder feet and the 80 mm bore. Use the G1/4 port for airline connections and verify stroke alignment to prevent side loading. Since cushioning is not provided, anticipate potential impact at end-of-stroke and consider external cushioning or limiting hardware if needed. Verify sensor placement for magnetic piston integration and calibrate control signals to match the 1–10 bar operating range.

The RM/92080/M/255 provides a theoretical force of 3016 N with a double-acting configuration. It operates from 1 to 10 bar and 14 to 145 psi, delivers reliable linear motion, and benefits from low-friction seals for smooth cycling. With a 255 mm stroke, it is suitable for mid-throw positioning, clamping, and transfer tasks in compact automation cells.

Yes, the cylinder uses an anodised aluminium barrel and a martensitic stainless steel piston rod, contributing to corrosion resistance. Its operating temperature range from -5 to 80 °C broadens applicability. While IP rating isn’t specified here, the non-corrodible construction generally supports reliable operation in demanding industrial environments with appropriate environmental guards.

Ideal for space-constrained automation tasks such as compact pick-and-place, transfer, or clamping on small assembly lines. The magnetic piston enables straightforward position sensing, making it well-suited for sensor-integrated control loops. Its robustness and 80 mm bore provide dependable force for medium-load positioning and repetitive actuations in packaging and machine tending.

The official datasheet is available here: https://cdn.norgren.com/pdf/en_1_5_141_RM_92000_M.pdf. It contains complete mechanical drawings, tolerances, porting details, and maintenance recommendations to support installation, commissioning, and lifecycle planning.