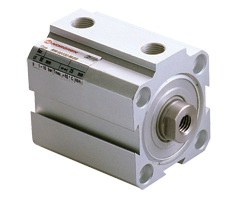

Norgren RM/92080/N2/10 Cyl - Compact Magnetic Piston

Part Number: RM/92080/N2/10

Quick Summary

RM/92080/N2/10 is a compact double-acting pneumatic cylinder designed for precise linear actuation in automated manufacturing lines. In tight spaces, engineers face alignment challenges, wear, and maintenance downtime that disrupt production. Key certifications like CE compliance, IP-rated protection, and SIL-ready safety interfaces are common expectations for this class. This model delivers a magnetic piston, long-life seals, and a fully non-corrodible specification, enabling full control-system versatility while withstanding demanding environments. The result is reduced downtime, easier integration with standard manifolds and controls, and lower total cost of ownership over the asset lifetime. For manufacturers seeking reliable, space-efficient actuation in packaging, automation, and process lines, RM/92080/N2/10 offers proven performance.

Product Information

Extended Description

RM/92080/N2/10 Norgren: One third the basic length of a corresponding ISO/VDMA model | Low friction, long life seal design | Fully non-corrodible specification | Standard magnetic piston for full control system versatility

Medium

Compressed air

Operating Temperature

-5 ... 80 °C, 23 ... 176 °F

Operating Pressure

1 ... 10 bar, 14 ... 145 psi

Port Size

G1/4

Cylinder diameter

80 mm

Stroke Length

10 mm

Operation

Double acting

Cushioning

No cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

3016 N

Materials - Barrel

Anodised aluminium alloy

Materials - Piston Rod

Stainless steel (martensitic)

Range

RM/92000/M

Brand

IMI Norgren

Feature: One third the basic length of a corresponding ISO/VDMA cylinder. Business Impact: Enables significant space savings and easier retrofits in compact cell layouts, panels, and tight automation spaces. Application: Ideal for small robotic cells and packaging lines where footprint is at a premium. Feature: Low friction, long-life seal design. Business Impact: Extends service intervals, reduces maintenance costs, and lowers total cost of ownership while maintaining consistent actuation. Application: High-cycle pick-and-place and transfer operations. Feature: Fully non-corrodible construction with anodised barrel and martensitic stainless piston rod. Business Impact: Improved durability in washdown and harsh environments, reducing replacement cycles. Application: Food & beverage or chemical-handling lines where corrosion resistance matters. Feature: Magnetic piston for versatile control-system integration. Business Impact: Easier sensing and feedback with PLCs and position sensors, improving automation reliability. Application: Sensor-ready actuation in machine tending and inline inspection. Feature: Operating range 1–10 bar and -5 to 80 °C. Business Impact: Broad compatibility with existing plant air systems, enabling flexible process changes. Application: General automation across multiple industries. Feature: G1/4 port and 80 mm bore with 10 mm stroke. Business Impact: Standardized plumbing simplifies installation and compatibility with common manifolds. Application: Compact actuation in confined spaces with standard fittings.

Get a Quick Quote for a Norgren RM/92080/N2/10

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren RM/92080/N2/10?

Enquire Now

FAQs

RM/92080/N2/10 uses a standard G1/4 port and magnetic piston, enabling easy mounting to common end brackets and manifolds. It integrates with standard sensing options (reed/Hall-effect) and supports industry adapters, simplifying retrofits and reducing installation time. Verify manifold spacing and align the bore to minimize deflection in compact, high-speed cells.

The cylinder delivers a theoretical force of 3016 N under rated conditions. It operates from 1 to 10 bar (14 to 145 psi). With an 80 mm bore and 10 mm stroke, this actuator provides robust linear motion across typical automation tasks. For continuous duty, ensure clean, dry compressed air and proper lubrication per system requirements.

Yes. The RM/92080/N2/10 combines low-friction seals, a magnetic piston, and corrosion-resistant construction to support high-cycle requirements. It is suited for pick-and-place, clamping, and transfer steps in packaging lines where repeatable positioning and reliable actuation are critical. For extended life, pair with proper filtration and routine maintenance.

This model aligns with industry expectations for robust pneumatic actuators, with considerations for CE compliance, IP-rated variants, and SIL-ready safety interfaces within the Norgren family. Always verify the specific unit’s documentation for certified status and ensure the control system and safety interlocks meet local regulatory requirements.

Plan regular inspection of seals and moving components to maximize uptime. The long-life seal design and magnetic piston reduce maintenance frequency and sensor wiring complexity. Evaluate total cost of ownership by factoring in extended service intervals, energy efficiency from lower leakage potential, and faster installation times on retrofit projects.