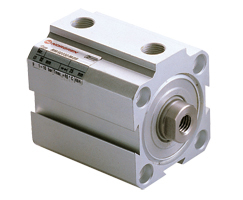

Norgren RM/92080/N4/15 Pneumatic Cylinder - Magnetic Piston

Part Number: RM/92080/N4/15

Quick Summary

Norgren RM/92080/N4/15 is a compact double-acting pneumatic cylinder designed for precise actuation in automation lines. In constrained spaces, engineers often struggle to fit a long-stroke actuator while maintaining performance and reliability. Note: Specific certifications such as CE, SIL, or IP ratings are not listed in the provided data; verify with the datasheet for compliance. This model uses an anodised aluminium barrel, a martensitic stainless-steel piston rod, and a magnetic piston to deliver long life, reduced wear, and full control-system versatility; these features support reliable performance in high-cycle applications. For OEMs and maintenance teams, it offers straightforward mounting with G1/4 porting and compact form, supporting cost-effective integration in pneumatic systems.

Product Information

Extended Description

RM/92080/N4/15 Norgren: One third the basic length of a corresponding ISO/VDMA model | Low friction, long life seal design | Fully non-corrodible specification | Standard magnetic piston for full control system versatility

Medium

Compressed air

Operating Temperature

-5 ... 80 °C, 23 ... 176 °F

Operating Pressure

1 ... 10 bar, 14 ... 145 psi

Port Size

G1/4

Cylinder diameter

80 mm

Stroke Length

15 mm

Operation

Double acting

Cushioning

No cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

3016 N

Materials - Barrel

Anodised aluminium alloy

Materials - Piston Rod

Stainless steel (martensitic)

Range

RM/92000/M

Brand

IMI Norgren

Feature: 80 mm bore and 15 mm stroke create a compact geometry. Business Impact: Enables denser machine layouts, reduces enclosure size and wiring complexity, and lowers overall system footprint. Application: Ideal for compact pick-and-place cells and small actuator tasks on constrained automation lines. Feature: Magnetic piston design provides ready-made sensor compatibility. Business Impact: Facilitates reliable position feedback and easier integration with proximity sensors or controllers, reducing setup time and wiring. Application: Sensor-ready actuation in automated assembly and robotics fixtures. Feature: Anodised aluminium barrel and martensitic stainless-steel piston rod deliver non-corrodible durability. Business Impact: Extends service life in challenging environments, lowers maintenance needs, and improves total cost of ownership. Application: Heavy-duty factory floors, washdown areas, and high-cycle processes. Feature: Low-friction, long-life seal design reduces wear and energy consumption. Business Impact: Increases cycle life, decreases lubrication events, and lowers operating costs over time. Application: High-cycle pick-and-place and repetitive clamping tasks. Feature: Operating range supports standard pneumatic systems with G1/4 porting (1–10 bar, -5 to 80 °C). Business Impact: Broad compatibility with existing compressors and clean-air supply, with predictable performance across environments. Application: General automation, packaging, and material handling lines. Feature: Compact form factor is complemented by the RM/92000/M range, offering straightforward integration into retrofits and new builds. Business Impact: Accelerates installation timelines and reduces engineering overhead. Application: OEM projects and retrofit SKUs where space and compatibility matter.

Get a Quick Quote for a Norgren RM/92080/N4/15

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren RM/92080/N4/15?

Enquire Now

FAQs

RM/92080/N4/15 is designed around a compact 80 mm bore and standard G1/4 porting, with a range aligned to the RM/92000/M family. While it emphasizes space efficiency and sensor-ready mounting via a magnetic piston, always verify mounting hole patterns and rod end provisions against your machine drawings. If retrofit is required, confirm bolt circle, stroke, and port alignment prior to installation.

The cylinder operates between 1 and 10 bar (14–145 psi) and tolerates temperatures from -5 to 80 °C (23 to 176 °F). This makes it suitable for most factory air systems and moderate-temperature environments. For extreme conditions, consult the datasheet to assess seals, lubrication, and any required coatings.

The magnetic piston enables straightforward feedback with non-contact sensors, simplifying control-system integration and wiring. It supports reliable position sensing in high-cycle applications, improving repeatability and traceability without adding mechanical complexity or external magnets that could affect performance.

Yes. The model is designed with a compact geometry and features a one-third shorter length than comparable ISO/VDMA models, while delivering robust force (3016 N) and stroke in an 80 mm bore cylinder. This enables tighter line layouts, easier enclosure planning, and potential capital savings in space-constrained applications.

With a low-friction, long-life seal design and corrosion-resistant materials, routine maintenance tends to be minimal. Monitor for seal wear in high-cycle use and ensure clean, dry compressed air. The magnetic piston aids sensor reliability, but verify sensor alignment during periodic inspection to maintain accurate position feedback.