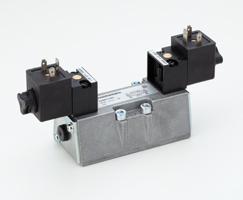

Norgren SXE9774-Z50-81-33N ISO Star Valve - IP65

Part Number: SXE9774-Z50-81-33N

Quick Summary

ISO Star Valve SXE9774-Z50-81-33N is a solenoid valve for compressed air control in automated manufacturing. Many users struggle with short life, high power draw, and sealing challenges under fluctuating pressures. This device carries IP65 protection with sealed plug and ISO 5599-1 conformity, ensuring rugged performance, while the diecast aluminium body resists corrosion. Coupled with a broad range of sub-bases and accessories, it reduces footprint, simplifies integration, and improves uptime for reliable, cost-efficient automation.

Product Information

Extended Description

SXE9774-Z50-81-33N Norgren: Specially coated glandless spool and sleeve for extremely long life | Low power solenoids and manual override as standard | Wide range of sub-bases and accessories

Medium

Compressed air

Operating Temperature

-15 ... 50 °C, 5 ... 122 °F

Operating Pressure

2 ... 16 bar, 29 ... 232 psi

Standard

ISO 5599-1

Port Size

ISO 2

Actuation

Solenoid pilot / Solenoid pilot

Function

COE

ISO Size

ISO #2

Valve operation

5/3

Flow

2450 l/m

Materials - Body

Diecast aluminium

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65 (with sealed plug)

Dimensions - Height

55 mm

Dimensions - Length

189 mm

Dimensions - Width

79 mm

Weight

1.2 kg

Country of Origin

Czechia

Range

SXE

Series

ISO Star

Brand

IMI Norgren

M/P15737

Electrical plug with cable gland

Glandless spool and sleeve coating reduce wear, delivering extremely long life. This translates to lower maintenance costs and fewer unplanned shutdowns, improving reliability in high-cycle automation environments. Application: conveyor systems and packaging lines where valve actuation is frequent and reliability is mission-critical. Low power solenoids and standard manual override reduce energy usage and maintenance complexity. The energy savings are notable across multi-valve banks, lowering total system power draw and enabling safer, cooler operation. Application: energy-conscious OEM lines and retrofit projects where reducing heat and electrical load matters. Standard ISO 2 port size and ISO 5599-1 compatibility simplify installation with existing sub-bases and accessories, reducing integration time and leakage risk. Application: retrofit projects and modular automation setups.

Get a Quick Quote for a Norgren SXE9774-Z50-81-33N

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren SXE9774-Z50-81-33N?

Enquire Now

FAQs

SXE9774-Z50-81-33N is designed around ISO 2 port sizing and ISO 5599-1 standards, enabling straightforward integration with standard sub-bases and accessory kits. It supports a range of mounting bases and electrical plugs (M/P15737) for reliable glandless spool actuation. When pairing with existing automation panels, verify base footprint and port orientation to ensure leak-free connections and minimal plumbing adaptations.

The valve operates with a 5/3 configuration and delivers a flow capacity of up to 2450 l/m across a working pressure range of 2 to 16 bar (29 to 232 psi). This makes it suitable for medium-to-high demand actuations in automation lines. In practice, you’ll see consistent response times and stable actuation across moderate temperature swings, which supports reliable cycle rates in high-throughput equipment.

Yes. The SXE9774-Z50-81-33N carries IP65 protection with a sealed plug, protecting internal components from dust ingress and water jets. This makes it well-suited for harsh production floors, packaging lines, and conveying systems where exposure to dust, humidity, or wash-down processes is common. Proper installation within a protected enclosure further enhances longevity.

Key certifications include IP65 ingress protection and ISO 5599-1 standard compliance, ensuring compatibility with established pneumatics practices. Maintenance considerations are centered on inspecting the glandless spool area for wear, verifying seals (nitrile rubber) integrity, and confirming that the solenoid coils exhibit low power draw. Routine checks aligned with the system’s maintenance schedule help maximize uptime and lifecycle cost savings.

The glandless spool design and low-power solenoids contribute to extended service life and lower energy costs, reducing maintenance intervals and energy consumption in multi-valve banks. When integrated with compatible sub-bases and a robust electrical connection, the valve lowers total cost of ownership by minimizing downtime, simplifying installation, and enabling compact, modular control architectures that scale with production demand.