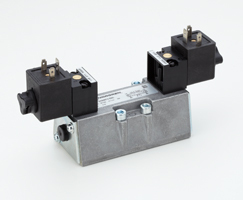

Norgren SXE9874-Z50-81-33N ISO Star Valve - IP65

Part Number: SXE9874-Z50-81-33N

Quick Summary

The SXE9874-Z50-81-33N is a solenoid-operated ISO Star valve designed for precise compressed air control in automation systems. In demanding environments, glandless spool wear and higher power draw can drive maintenance costs and downtime. This valve delivers IP65 protection with a sealed plug and ISO 5599-1 compatibility, offering reliable performance in factory floors and harsh environments. Its modular design, plus a range of sub-bases and accessories, simplifies integration with ISO 2 port systems and supports scalable automation investments.

Product Information

Extended Description

SXE9874-Z50-81-33N Norgren: Specially coated glandless spool and sleeve for extremely long life | Low power solenoids and manual override as standard | Wide range of sub-bases and accessories

Medium

Compressed air

Operating Temperature

-15 ... 50 °C, 5 ... 122 °F

Operating Pressure

2 ... 16 bar, 29 ... 232 psi

Standard

ISO 5599-1

Port Size

ISO 2

Actuation

Solenoid pilot / Solenoid pilot

Function

COP

ISO Size

ISO #2

Valve operation

5/3

Flow

2450 l/m

Materials - Body

Diecast aluminium

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65 (with sealed plug)

Dimensions - Height

55 mm

Dimensions - Length

189 mm

Dimensions - Width

79 mm

Weight

1.2 kg

Country of Origin

Czechia

Range

SXE

Series

ISO Star

Brand

IMI Norgren

M/P15737

Electrical plug with cable gland

Specially coated glandless spool and sleeve delivers extremely long life in high-cycle pneumatic circuits, reducing maintenance intervals and spare-part costs. This translates to higher line uptime on packaging and processing lines, with lower total cost of ownership. Low power solenoids and a standard manual override enable energy-efficient operation and quick manual intervention during fault or setup, supporting safer start-up and faster changeovers. A wide range of sub-bases and accessories means easy mounting on existing manifolds, reducing installation time and risk of misalignment. The valve’s ISO 2 port size and 5/3 operation provide flexible circuit design, while the IP65 rating with sealed plug guards against dust and water ingress in open production areas. Diecast aluminium body and nitrile seals deliver robust performance in industrial environments, helping you meet maintenance and uptime targets.

Get a Quick Quote for a Norgren SXE9874-Z50-81-33N

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren SXE9874-Z50-81-33N?

Enquire Now

FAQs

This valve uses ISO 2 port size and is designed for direct integration with ISO 5599-1 manifolds. It supports a range of sub-bases and mounting accessories, reducing installation time and misalignment risk. Ensure your base plate provides a stable, level surface and that wiring and inlet/outlet ports align with the footprint for a consistent seal and leak-free operation.

Key specs include 2-16 bar operating pressure, 2450 L/m flow, 5/3 valve operation, and IP65 protection with sealed plug. The medium is compressed air, and the valve uses a diecast aluminium body with nitrile seals. These combine to deliver reliable, energy-efficient operation with fast response in continuous production lines.

Yes. The 5/3 configuration and solenoid pilot actuation support precise, multi-position control in packaging machinery. The glandless spool and low-power solenoids reduce wear and energy use, while the option for manual override supports quick fault recovery. IP65 protection ensures resilience against dust and splashes common in packaging environments.

The valve is ISO 5599-1 compliant and carries an IP65 rating with a sealed plug. These certifications ensure compatibility with standardized pneumatic circuits and solid ingress protection for industrial environments, facilitating regulatory compliance, safer operation, and easier supplier interoperability in automation projects.

The glandless spool and coated components extend service life, reducing replacement intervals and downtime. Low power solenoids further cut energy costs, while the availability of sub-bases and accessories shortens installation time. Together, these factors contribute to lower total cost of ownership and faster time-to-value in automated production environments.