Norgren V415611D-C313A Valve - IP65 Protection

Part Number: V415611D-C313A

Quick Summary

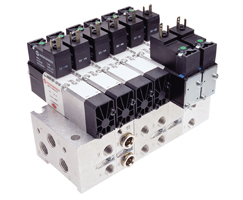

Norgren V415611D-C313A Valve is a high‑performance pneumatic valve for compact automation tasks. Engineers often grapple with bulky sub-base systems and costly field upgrades that halt production and complicate maintenance. This valve carries IP65 and NEMA 4 enclosures and aligns with ISO 15407‑1, ensuring reliable operation in washdowns and industrial dust zones. Designed for flexible sub-base configurations, easy conversion from internal to external pilot supply, and a flow of 680 L/min, it delivers uptime and scalable automation for modern lines.

Product Information

Extended Description

V415611D-C313A Norgren: High performance, compact design | Flexible sub-base system | Multipressure system capability | Wide range of accessories | Easy to convert from internal to external pilot supply | Valve exchange under pressure

Medium

Compressed air

Operating Temperature

-15 ... 50 °C, 5 ... 122 °F

Operating Pressure

2 ... 10 bar, 29 ... 145 psi

Standard

ISO 15407-1

Port Size

Sub-Base

Actuation

Solenoid pilot / Solenoid pilot

Function

APB

Valve operation

5/3

Flow

680 l/m

Materials - Body

Diecast aluminium

Materials - Seals

HNBR

Certification - IP Rating

IP65, NEMA 4

Dimensions - Height

77.5 mm

Dimensions - Length

115 mm

Dimensions - Width

18.5 mm

Weight

0.16 kg

Country of Origin

Czechia

Range

V41

Series

Mini ISO Valves

Brand

IMI Norgren

V10027-D00

15mm Plugs according to DIN 43650 Form C

Feature: Compact die-cast aluminium body with a footprint that fits tight panel spaces. Benefit: Reduces cabinet intrusion and installation costs, enabling more efficient automation layouts. Application: Ideal for confined packaging lines and conveyor controls where space is at a premium. Feature: 5/3 valve with solenoid pilot actuation. Benefit: Simplifies control wiring and improves switch-activation reliability, boosting line throughput. Application: Common in pick-and-place and material handling stations where fast cycling is required. Feature: ISO 15407-1 standard and Sub-Base port sizing. Benefit: Ensures interchangeability and quick mounting for standardized automation cells. Application: Retrofit projects or multi-vendor lines seeking proven compatibility. Feature: Flexible sub-base system and internal/external pilot supply switch. Benefit: Reduces downtime during configuration changes and enables on-site adaptability. Application: Customizable automation islands and modular control panels. Feature: Material and seals – Diecast aluminium body, HNBR seals. Benefit: Robust weight-to-strength ratio with resistance to wear and chemical compatibility, extending service intervals. Application: Harsh production environments with frequent washdowns. Feature: High flow and wide operating window – 680 L/min, 2–10 bar, -15 to 50 °C. Benefit: Maintains performance under varying process demands and supply pressures, enhancing system efficiency. Application: Air gate valves and process lines requiring steady air delivery.

Get a Quick Quote for a Norgren V415611D-C313A

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren V415611D-C313A?

Enquire Now

FAQs

Install on an ISO 15407-1 compliant sub-base, mount the valve on a clean panel, and tighten fittings to a leak-tested standard. Use the V10027-D00 15mm DIN 43650 Form C plug for electrical connections and feed the pilot supply with 2–10 bar compressed air. The valve supports conversion from internal to external pilot supply and can be swapped under pressure, minimizing downtime.

This is a solenoid-piloted 5/3 valve with APB function and a maximum flow of 680 L/min. It operates at 2–10 bar and withstands temperatures from -15 to 50 °C. The body is diecast aluminium with HNBR seals, providing IP65 and NEMA 4 protection. Dimensions are 115 mm × 18.5 mm × 77.5 mm and weight is 0.16 kg.

Yes. Its compact footprint, IP65/NEMA 4 protection, and 680 L/min flow support fast, reliable actuation in tight packaging zones. The flexible sub-base system and easy pilot-supply conversion reduce installation time and enable quick reconfiguration for evolving packaging lines.

The valve complies with ISO 15407-1 for standardization and provides IP65, NEMA 4 enclosure protection. It is part of the IMI Norgren Mini ISO Valves family (V41 range), designed for robustness in industrial environments and cross-compatibility with common automation components.

Key maintenance advantages include the ability to exchange the valve under pressure and convert pilot sourcing without disassembly, reducing downtime. HNBR seals resist wear, while the compact, modular sub-base design lowers spare parts inventory and accelerates repair timelines, contributing to lower total cost of ownership.