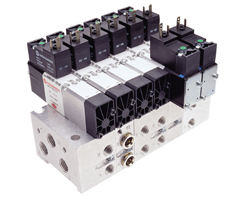

Norgren V415C11D-C313A Mini ISO Valve - IP65 Certified

Part Number: V415C11D-C313A

Quick Summary

The Norgren V415C11D-C313A Mini ISO Valve provides compact solenoid-controlled pneumatic actuation for automation lines. Many projects stall due to space constraints and difficult field servicing, so this valve is designed for quick mounting and simple field servicing. It aligns with ISO 15407-1, IP65 and NEMA 4 requirements, supporting robust performance in harsh environments. Beyond protection, developers value its flexible sub-base system, external pilot options, and the ability to swap components under pressure. These capabilities translate into shorter installation times, lower lifecycle costs, and consistent performance in line automation applications. Engineers also benefit from broad accessory compatibility and straightforward electrical connection via standard DIN 43650 form C plugs.

Product Information

Extended Description

V415C11D-C313A Norgren: High performance, compact design | Flexible sub-base system | Multipressure system capability | Wide range of accessories | Easy to convert from internal to external pilot supply | Valve exchange under pressure

Medium

Compressed air

Operating Temperature

-15 ... 50 °C, 5 ... 122 °F

Operating Pressure

2.5 ... 10 bar, 36 ... 145 psi

Standard

ISO 15407-1

Port Size

Sub-Base

Actuation

Solenoid pilot / Spring and air spring return

Function

NO/NC

Valve operation

2x3/2

Flow

610 l/m

Materials - Body

Diecast aluminium

Materials - Seals

HNBR

Certification - IP Rating

IP65, NEMA 4

Dimensions - Height

77.5 mm

Dimensions - Length

115 mm

Dimensions - Width

18.5 mm

Weight

0.18 kg

Country of Origin

Czechia

Range

V41

Series

Mini ISO Valves

Brand

IMI Norgren

V10027-D00

15mm Plugs according to DIN 43650 Form C

Feature: Compact, high-flow valve body. Business impact: The 610 L/min flow at 2.5–10 bar delivers fast actuation without adding footprint, boosting cycle rates and line throughput. Application: Ideal for tight automation zones in packaging, labeling, and pick-and-place stations where every millimeter matters. Additionally, the diecast aluminium body provides rigidity while keeping weight down, aiding fast response. The valve supports a wide range of system pressures, enabling use across multiple lines. Feature: Flexible sub-base system and pilot adaptability. Business impact: Enables straightforward mounting on standard manifolds and easy conversion from internal to external pilot supply, reducing installation time and spare-parts diversity. Application: Retrofit projects and new lines requiring modular valve islands in automotive assembly or material handling. This also simplifies spare-parts planning. Feature: Multipressure capability and high reliability. Business impact: Works across 2.5–10 bar supply, reducing the need for multiple valve variants, while the solenoid pilot/spring return ensures stable actuation. Application: Multi-zone conveyors and automated equipment with varying air pressure across zones. That means fewer SKU variants and simpler stocking. This is especially valuable for line expansions. Feature: Broad accessory ecosystem and plug compatibility. Business impact: A wide range of accessories and 15 mm DIN 43650 Form C plugs simplify integration, cut wiring time, and lower wiring error risk. Application: Custom pneumatic circuits and machine-tending setups needing quick field wiring. The plug compatibility also helps reduce electrical noise and miswirings. Feature: Durable construction and protection. Business impact: Diecast aluminium body with HNBR seals plus IP65/NEMA 4 protection deliver rugged performance in dusty or washdown environments, reducing unplanned downtime. Application: Food/bev packaging lines, automotive fixtures, and other harsh manufacturing environments. Its rugged construction minimizes impact from minor knocks. Sealing contributes to long service life in corrosive environments. Feature: Maintenance-friendly design and under-pressure exchange. Business impact: Easy valve exchange under pressure and straightforward maintenance workflows shorten downtime and improve OEE. Application: High-demand production lines where uptime matters. Field technicians appreciate clear diagnostic indicators and straightforward component replacement. Training materials and datasheets expedite onboarding.

Get a Quick Quote for a Norgren V415C11D-C313A

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren V415C11D-C313A?

Enquire Now

FAQs

Install the valve onto a compatible sub-base manifold, then connect the external pilot supply as needed. Use the standard V10027-D00 15 mm plugs according to DIN 43650 Form C for reliable electrical connection. The valve supports conversion from internal to external pilot without major disassembly, simplifying retrofits and ongoing maintenance.

Electrical connections use the V10027-D00 15 mm plugs per DIN 43650 Form C. Ensure your control voltage matches the coil requirement and wire through standard terminal blocks to minimize noise and miswiring. The DIN Form C plugs enable quick, vibration-tolerant connections suitable for industrial environments.

Yes. The valve is rated IP65 and NEMA 4, providing protection against dust ingress and washdown exposure. Constructed with a diecast aluminium body and HNBR seals, it is designed to endure harsh production environments, reducing maintenance frequency and unplanned downtime.

Port size is Sub-Base, enabling straightforward mounting on standard manifolds and ease of integration into modular valve islands. This makes retrofits and new installations quicker and reduces the need for adapters or custom fittings.

The V415C11D-C313A supports valve exchange under pressure and easy pilot-supply conversion, shortening downtime during maintenance or upgrades. Its durable construction, broad accessory compatibility, and reliable IP65/NEMA 4 protection contribute to lower total cost of ownership and higher line efficiency over the long term.