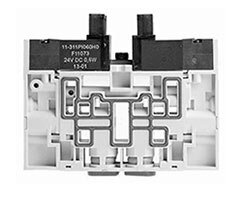

Norgren VM104A11AB313B Valve Island with 430 L/min flow IP65

Part Number: VM104A11AB313B

Quick Summary

Norgren VM104A11AB313B Valve Island supports compact, high-flow pneumatic control for automated lines in packaging and manufacturing. Engineers often struggle with installation rigidity, space constraints, and unreliable performance in harsh environments. The design delivers IP65 protection and a long life up to 100 million cycles, while supporting Fieldbus, multipole, or individually wired configurations for installation flexibility. With a compact body built from engineered PPA co-polymer and nitrile seals, this VM10 valve island resists wear in demanding environments. Operating across -5 to 50 °C and 3 to 8 bar expands its applicability, from food packaging lines to automotive assembly. The combination reduces panel footprint, wiring complexity, and maintenance costs, helping engineers meet tight project timelines and budget targets.

Product Information

Extended Description

VM104A11AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | High flow from 10 mm (VM10) valve width | Long life up to 100 million cycles | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

4mm PIF

Actuation

Solenoid pilot / Solenoid pilot

Function

NC

Valve operation

2x3/2

Flow

430 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

10.5 mm

Dimensions - Length

78.6 mm

Dimensions - Width

65.7 mm

Weight

0.06 kg

Country of Origin

Czechia

Range

VM10

Brand

IMI Norgren

High-flow capability in a compact VM10 package translates to increased throughput and reduced panel real estate. The 430 L/min flow enables faster cycle times, which lowers overall line downtime and boosts productivity on demanding applications such as packaging and assembly lines. This feature directly supports lean manufacturing goals by speeding up material handling and product throughput while preserving energy efficiency. Flexible actuation options with solenoid pilot wiring allow Fieldbus, multipole, or individually wired configurations. Business impact: simplified installation, reduced wiring errors, and easier future upgrades. Application examples include automated lines where quick reconfiguration is required following line changes or product mix shifts, such as in packaging or automotive sub-assembly. IP65-rated enclosure paired with an engineered PPA co-polymer body and nitrile seals delivers robust protection against dust and water ingress in harsh environments. The result is lower maintenance costs and longer service intervals, ideal for washdown zones or dusty production floors. Compact dimensions and integral push-in fittings minimize panel footprint and simplify assembly, enabling faster panel builds and easier field servicing. This supports on-site changes without major redesigns, particularly in constrained spaces and retrofits. Long service life up to 100 million cycles under typical industrial loads reduces replacement frequency and downtime, delivering strong total cost of ownership benefits for high-cycle applications such as continuous packaging or high-volume automation.

Get a Quick Quote for a Norgren VM104A11AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM104A11AB313B?

Enquire Now

FAQs

The VM104A11AB313B offers Fieldbus, multipole, or individually wired configurations, enabling installation flexibility across a range of controllers and panel layouts. It also features integral push-in fittings and a 4 mm PIF port design to simplify piping and speed up commissioning in compact control cabinets.

This valve island provides a high flow of 430 L/min and supports an operating pressure range of 3 to 8 bar. With a temperature range of -5 to 50 °C, it is suitable for many industrial environments, delivering reliable actuation for fast, repeatable pneumatic control.

Yes. It features IP65 ingress protection and a compact, durable build using an engineered PPA body with nitrile seals. This combination offers resistance to dust and water exposure, helping maintain performance in demanding manufacturing and packaging environments.

The VM10 family is designed for long life, with performance capable of up to 100 million cycles under typical industrial use. This translates to reduced maintenance frequency, lower downtime, and a lower total cost of ownership on high-cycle automation lines.

Applications including high-throughput packaging, automotive sub-assembly, and general automation lines benefit from the combination of high flow, compact form, and flexible wiring. The 4 mm PIF ports, solid IP65 protection, and fieldbus compatibility support rapid integration into existing systems with minimal panel space and wiring changes.