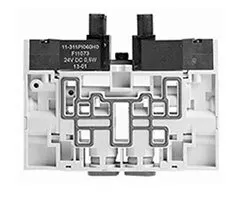

Norgren VM106517AB313B Valve Slice - VM10 Series IP65

Part Number: VM106517AB313B

Quick Summary

The Norgren VM106517AB313B Valve Slice delivers compact, high-flow control for pneumatic automation systems. In tight installations, flexible wiring and reliable performance are critical to minimize downtime and rework. IP65 protection and a long life up to 100 million cycles help ensure robust operation in dusty, wet environments, while fieldbus readiness supports scalable control. With VM10 compatibility and integral push-in fittings, customers gain faster installation, reduced panel space, and lower total cost of ownership.

Product Information

Extended Description

VM106517AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | High flow from 10 mm (VM10) valve width | Long life up to 100 million cycles | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

6mm PIF

Actuation

Solenoid pilot / Spring return

Valve operation

5/2

Flow

430 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

10.5 mm

Dimensions - Length

78.6 mm

Dimensions - Width

65.7 mm

Weight

0.051 kg

Country of Origin

Czechia

Range

VM10

Brand

IMI Norgren

This VM10 Series Valve Slice is designed to maximize throughput in compact spaces. Its wide flow (430 l/m) from a narrow 10 mm width enables higher productivity without expanding equipment footprints. The option for fieldbus, multipole, or individually wired configurations offers installation flexibility across automation lines. Durable construction uses an engineered PPA co-polymer body with nitrile seals, delivering reliable performance in standard compressed air systems and demanding environments. The IP65 rating protects against dust and water ingress, while integral push-in fittings simplify field assembly and maintenance. The Lifespan is rated up to 100 million cycles, supporting high-cycle applications and reducing replacement intervals. 6 mm PIF port, 3–8 bar operating window, and 23–122 °F operating range make it compatible with VM10-based islands and retrofits.

Get a Quick Quote for a Norgren VM106517AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM106517AB313B?

Enquire Now

FAQs

VM106517AB313B is designed for VM10 series valve islands and uses 6 mm push-in (PIF) ports. Its compact footprint and integral push-in fittings simplify panel routing, reduce assembly time, and ensure reliable connections even in confined spaces. The device supports fieldbus wiring or individual wiring configurations to match your control architecture.

The valve delivers 430 liters per minute of flow at 3 to 8 bar, enabling rapid actuation of pneumatic circuits. Its 5/2 valve configuration and compact 10 mm width support dense valve islands, increasing channel density and overall system throughput while maintaining stable switching performance across the operating range of −5 to 50 °C.

Yes. The valve is IP65 rated, providing protection against dust ingress and water jets, making it suitable for damp or wash-down environments. Built with an engineered PPA co-polymer body and nitrile seals, it maintains performance in typical industrial conditions while offering long life for continuous operation.

The body is engineered PPA co-polymer with nitrile seals, and the unit carries an IP65 rating for environmental protection. With 6 mm PIF ports, 3–8 bar operating pressure, and a 100 million cycle life potential, the VM106517AB313B minimizes maintenance intervals and supports long-term reliability across VM10-based configurations.

The device’s long life—up to 100 million cycles—reduces replacement frequency in high-cycle applications, lowering maintenance costs and downtime. Its compact form factor and push-in fittings speed installation, while fieldbus compatibility and VM10 ecosystem ensure scalable control across multiple hydraulic/pneumatic lines, improving overall line productivity and asset utilization.