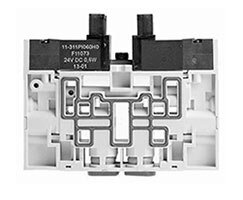

Norgren VM106B11AB313B Valve Slice - High Flow IP65

Part Number: VM106B11AB313B

Quick Summary

VM106B11AB313B valve slice provides compact, high-flow control for compressed air systems in automation lines. Engineers often deal with limited installation flexibility and wear; this device supports fieldbus or solenoid pilot setups and long service life. It features IP65 ingress protection and a life expectancy up to 100 million cycles, delivering reliability in harsh environments. Compact, lightweight design and integrally fitting push-in ports reduce assembly time while enabling scalable, modular automation. These characteristics translate to lower maintenance costs, improved uptime, and predictable performance across pneumatic networks for manufacturers seeking energy efficiency and faster time-to-market.

Product Information

Extended Description

VM106B11AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | High flow from 10 mm (VM10) valve width | Long life up to 100 million cycles | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

6mm PIF

Actuation

Solenoid pilot / Solenoid pilot

Function

NO

Valve operation

2x3/2

Flow

430 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

10.5 mm

Dimensions - Length

78.6 mm

Dimensions - Width

65.7 mm

Weight

0.057 kg

Country of Origin

Czechia

Range

VM10

Brand

IMI Norgren

Feature: High-flow performance from the VM10 valve width enables greater throughput with minimal pressure drop. Business Impact: Higher production rates and reduced cycle times translate to tangible throughput gains on automated lines. Application: Automotive assembly, packaging and process lines requiring rapid actuation without compromising standby power. Feature: Fieldbus, multipole or individually wired configurations provide installation flexibility. Business Impact: Simplified wiring schemes reduce panel space and commissioning time, lowering engineering effort and changeover costs. Application: Modular valve islands and flexible automation networks in factory floors. Feature: IP65 protection and a compact, lightweight form factor. Business Impact: Superior ruggedness in washdown or dusty environments lowers warranty claims and downtime. Application: Robotic cells, conveyor lines and machine centers exposed to harsh conditions. Feature: Integral push-in fittings and 6 mm PIF port size enable rapid, reliable plumbing. Business Impact: Faster installation with fewer fittings minimizes leak points and assembly time. Application: OEM manifolds and field-mounted control panels. Feature: Materials - Engineered PPA body with nitrile seals deliver chemical and wear resistance. Business Impact: Long-term durability reduces maintenance cycles and total cost of ownership. Application: Continuous-duty pneumatic systems across manufacturing environments. Feature: Long life up to 100 million cycles and a 3–8 bar operating range. Business Impact: Predictable lifecycle costs and dependable performance under typical plant air conditions. Application: High-cycle automation in packaging, automation cells and process lines.

Get a Quick Quote for a Norgren VM106B11AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM106B11AB313B?

Enquire Now

FAQs

The VM106B11AB313B uses standard 6 mm PIF ports and is designed for fieldbus, multipole, or individual wiring. Its compact 78.6 mm length and integral push-in fittings simplify mounting on VM10 island configurations, reducing wiring complexity and enabling rapid commissioning.

Key specs include flow of 430 l/m, operating pressure 3–8 bar, and a temperature range of -5 to 50 °C. Coupled with IP65 protection and life expectancy up to 100 million cycles, these factors deliver consistent actuation, reduced maintenance, and predictable energy usage in automated lines.

Yes. With NO function (2x3/2 valve operation), solenoid pilot actuation, and compact form factor, it fits tight panel spaces and scalable automation networks typical in packaging and assembly lines, while supporting fast redirection of air flow and reliable actuation cycles.

The unit carries an IP65 protection rating, ensuring ingress protection against dust and water jet exposure in industrial environments. This makes it well-suited for washdown areas and harsh factory floors where robust sealing and reliability are required.

The combination of long life up to 100 million cycles, durable nitrile seals, and a lightweight, push-in fitting design reduces maintenance intervals and installation time. The result is lower total cost of ownership, reduced downtime, and faster time-to-value in automated pneumatic networks.