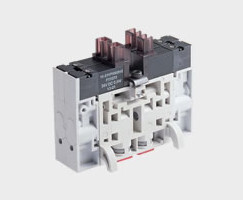

Norgren VM158511AB313B Valve Island - IP65, 100M cycles

Part Number: VM158511AB313B

Quick Summary

VM158511AB313B Valve Island enables compact, flexible pneumatic control for automated assembly lines. Engineers often struggle with install-time complexity and space constraints in tight machine layouts. IP65 rating protects against dust and water ingress while the design supports Fieldbus, multipole, or individually wired configurations, delivering scalable connectivity. With a long service life of up to 100 million cycles, this valve island reduces downtime and replacement costs. The VM15 family also offers high-density valve integration, enabling up to 32 solenoids (16 valves) in a single island. By combining a compact form with integral push-in fittings and lightweight construction, it streamlines installation, cabinet footprint, and maintenance routines, delivering tangible total cost of ownership benefits in demanding industrial environments.

Product Information

Extended Description

VM158511AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | Long life up to 100 million cycles | Up to 32 solenoids (16 valves) in one valve island | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

8mm PIF

Actuation

Solenoid pilot / Solenoid pilot

Valve operation

5/2

Flow

1000 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

14.7 mm

Dimensions - Length

93.6 mm

Dimensions - Width

76 mm

Weight

0.225 kg

Country of Origin

Czechia

Range

VM15

Brand

IMI Norgren

Feature: Flexible wiring options — Fieldbus, multipole, or individually wired connections. Benefit: Simplified integration with existing networks and reduced panel wiring, cutting commissioning time. Application: Automotive, packaging, and generic factory automation where multiple valve signals must be centralized. Feature: High-density configuration — up to 32 solenoids (16 valves) in one valve island. Benefit: Dramatically reduced cabinet footprint and shorter install times, enabling tighter machine layouts. Application: Conveyors, pick-and-place lines, and palletizing equipment requiring dense valve control. Feature: Long life — up to 100 million cycles. Benefit: Lower maintenance costs, reduced spare parts, and improved line uptime. Application: Continuous production lines in food, beverage, and electronics packaging where reliability is critical. Feature: IP65 protection. Benefit: Robust operation in dusty or damp environments, improving durability in outdoor or washdown areas. Application: Agricultural automation, outdoor packaging, and process lines with exposure to environmental elements. Feature: 8 mm PIF port size and 3–8 bar operating range with 1000 L/m flow. Benefit: Broad compatibility with common pneumatic circuits and predictable performance under load. Application: General purpose actuation in mid-scale automation projects. Feature: Engineered body and seals — Engineered PPA co-polymer body and nitrile seals. Benefit: Lightweight, chemical resistance, and dependable sealing for long-term operation. Application: Harsh manufacturing environments where material compatibility matters.

Get a Quick Quote for a Norgren VM158511AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM158511AB313B?

Enquire Now

FAQs

Begin by selecting an appropriate mounting location that minimizes wire runs. Mount the valve island using standard DIN rail or panel mounting hardware, then route compressed air to the 8 mm PIF ports. Connect fieldbus or individual solenoid signals according to your network architecture, ensuring proper polarity and secure push-in connections. Finally, test actuations in a staged sequence to confirm correct valve operation and leakage-free performance.

The VM158511AB313B operates between -5 and 50 °C (23 to 122 °F) and supports an operating pressure range of 3 to 8 bar (44 to 116 psi). It delivers a flow of up to 1000 L/min, suitable for demanding pneumatic circuits while maintaining reliable actuation across multiple valves in a single island.

Yes. The VM158511AB313B supports up to 32 solenoids (16 valves) in one valve island, enabling high-density control without requiring larger manifolds. This reduces cabinet footprint, shortens wiring runs, and simplifies diagnostics, making it ideal for compact packaging lines, robotic feeders, and other space-constrained automation tasks.

The valve island carries an IP65 protection rating, providing robust dust and water ingress protection suitable for harsh industrial environments. While IP65 is the primary certification specified, its rugged construction and fieldbus compatibility align with common industry standards for modular valve islands used across automation projects.

With a long life of up to 100 million cycles, the VM158511AB313B reduces downtime and spare-part consumption. Its compact, dense design shortens installation time and minimizes cabinet space, while flexible wiring options streamline upgrades and expansions, delivering lower total cost of ownership and a faster return on investment in mid-to-large scale automation projects.