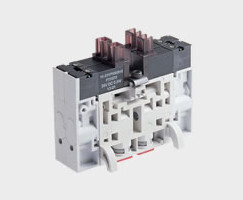

Norgren VM158517AB313B Valve Slice - IP65

Part Number: VM158517AB313B

Quick Summary

The Norgren VM158517AB313B valve slice enables compact, flexible pneumatic control for automation cells. Engineers often wrestle with wiring complexity and bulky manifolds, but this module offers fieldbus readiness, multipole options, and integral push-in fittings to simplify installation. With IP65 protection and a rated life of up to 100 million cycles, it withstands demanding environments while delivering reliable performance across -5 to 50 °C and 3 to 8 bar. The VM15 family design supports scalable island configurations, enabling up to 32 solenoids (16 valves) per island and reducing cabinet footprint and total system cost. This combination of density, durability, and ease of wiring makes it a practical choice for modern manufacturing lines.

Product Information

Extended Description

VM158517AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | Long life up to 100 million cycles | Up to 32 solenoids (16 valves) in one valve island | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

8mm PIF

Actuation

Solenoid pilot / Spring return

Valve operation

5/2

Flow

1000 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

14.7 mm

Dimensions - Length

93.6 mm

Dimensions - Width

76 mm

Weight

0.16 kg

Country of Origin

Czechia

Range

VM15

Brand

IMI Norgren

Fieldbus readiness and flexible wiring options help reduce panel complexity and shorten commissioning times. This VM158517AB313B supports multipole configurations or individual wiring, enabling engineers to tailor the valve island to the exact control architecture. In practice, you can deploy dense I/O islands on VM15 hardware and route signals with fewer cross-wires, streamlining maintenance and reducing downtime on automated lines. High-density valve islands allow up to 32 solenoids (16 valves) in a single island, delivering significant space savings and simpler field wiring. The business impact is lower cabinet footprint, reduced installation time, and easier future expansion as production lines scale. This is ideal for packaging and assembly lines where space is at a premium. Compact and lightweight design, with an engineered PPA body and nitrile seals, reduces weight in moving assemblies and minimizes energy usage during actuation. Integral push-in fittings speed installation and eliminate loose fittings, cutting leak points and maintenance costs. The VM15 island concept enables modular, scalable configurations for industrial automation, lowering total cost of ownership. Robust operating range and flow performance ensure predictability in real-world systems. With a -5 to 50 °C operating temperature and 3 to 8 bar operating pressure, the unit handles a wide range of pneumatic tasks. A maximum flow of 1000 L/min supports responsive actuation in medium to high-demand circuits, while 8 mm PIF port size aligns with common industrial fittings. Protection and durability come standard with an IP65-rated enclosure and a life expectancy up to 100 million cycles, supporting reliable operation in dusty environments and washdown scenarios. The 93.6 mm length and 76 mm width enable straightforward integration into modular valve islands; the 0.16 kg weight helps minimize dynamic loads on moving machinery.

Get a Quick Quote for a Norgren VM158517AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM158517AB313B?

Enquire Now

FAQs

The VM158517AB313B supports fieldbus-ready configurations with multipole wiring or individual wiring, enabling you to tailor the valve island to the control architecture. This flexibility simplifies panel design and reduces wiring complexity, making it easier to scale automation lines without replacing existing hardware.

Key specs include IP65 protection, operating temperature from -5 to 50 °C, operating pressure 3 to 8 bar, and a maximum flow of 1000 L/min. The unit is designed for up to 100 million actuator cycles, delivering durability in dust-prone or washdown environments while maintaining precise pneumatic control.

Yes. Its high-density island design (up to 32 solenoids per island), compact footprint, and quick-connect push-in fittings make it ideal for dense packaging and automated assembly lines where space, reliability, and fast changeovers are critical.

The VM158517AB313B features an IP65 enclosure rating, indicating robust ingress protection suitable for dusty and washdown environments. The specification emphasizes durability and reliability for industrial automation, though other certifications such as SIL or CE data are not provided in the current spec sheet.

The combination of fieldbus compatibility, integral push-in fittings, and a long service life reduces maintenance frequency and wiring points of failure. Its compact, dense package lowers cabinet size and material costs, while its durability minimizes replacement cycles, delivering a favorable total cost of ownership in repetitive automation tasks.