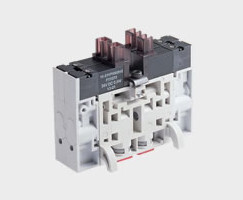

Norgren VM158C11AB313B Valve Slice - IP65 Certified

Part Number: VM158C11AB313B

Quick Summary

The VM158C11AB313B valve slice from Norgren provides compact multi-solenoid control for pneumatic valve islands in automated lines. Engineers often struggle with wiring complexity and limited installation space in dense automation cells. With IP65 protection and a proven life of up to 100 million cycles, the VM15 platform delivers reliable operation in washdown environments and harsh factories. Its compact, lightweight form factor and flexible wiring options reduce footprint and commissioning time, while integral push-in fittings speed field installation. These design choices enable scalable automation, lower maintenance costs, and faster time-to-production for modern manufacturing lines.

Product Information

Extended Description

VM158C11AB313B Norgren: Fieldbus, multipole or individually wired for installation flexibility | Long life up to 100 million cycles | Up to 32 solenoids (16 valves) in one valve island | Compact and lightweight | Integral push in fittings

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

3 ... 8 bar, 44 ... 116 psi

Port Size

8mm PIF

Actuation

Solenoid pilot / Solenoid pilot

Function

NO/NC

Valve operation

2x3/2

Flow

965 l/m

Materials - Body

Engineered PPA co-polymer

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

14.7 mm

Dimensions - Length

93.6 mm

Dimensions - Width

76 mm

Weight

0.1 kg

Country of Origin

Czechia

Range

VM15

Brand

IMI Norgren

Up to 32 solenoids (16 valves) can be wired in a single valve island, delivering high-density control. This organization reduces panel footprint, simplifies harness routing, and lowers wiring costs across automation cells. It is well suited for complex lines such as bottleneck assembly or multi-robot conveyors. Flexible wiring options include fieldbus, multipole, or individually wired configurations to fit existing controls. This flexibility speeds integration, reduces commissioning time, and minimizes the risk of miswiring in critical lines. Compact footprint and integral push-in fittings further speed setup and ensure reliable leak-free connections. The VM15 platform supports rapid installation and consistent performance, even in space-constrained environments. Long life up to 100 million cycles lowers maintenance demands and extends equipment uptime. The design supports high-cycle applications like continuous feeding, testing rigs, and automated packing lines. Users benefit from reduced spare parts and lower replacement intervals in production environments. Integral push-in fittings enable fast, secure field wiring with minimal tools. This reduces installation time and supports rapid maintenance without compromising system integrity. The VM15 platform’s compatibility with 8 mm PIF ports streamlines tubing and actuation. IP65 protection ensures dust ingress protection and washdown tolerance in challenging environments. Engineered PPA body and nitrile seals provide chemical resistance and durable performance across compressed air systems. Compact, lightweight construction supports installation in space-constrained facilities such as automotive and food & beverage lines. Operating pressure ranges from 3 to 8 bar, with 8 mm PIF porting for reliable actuation. Flow capacity is 965 liters per minute, supporting rapid response and accurate valve control. With fieldbus versatility and compact form, VM158C11AB313B enables scalable automation while reducing total cost of ownership.

Get a Quick Quote for a Norgren VM158C11AB313B

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VM158C11AB313B?

Enquire Now

FAQs

VM158C11AB313B supports fieldbus, multipole, or individually wired configurations, enabling seamless integration with existing control systems. The 8 mm PIF ports and flexible wiring options reduce commissioning time and wiring errors on dense automation layouts.

Key specs include NO/NC function, 2x3/2 valve operation, a flow of 965 l/min, and an operating pressure range of 3 to 8 bar. Port size is 8 mm PIF, making actuation reliable across typical compressed air systems.

Yes. The unit carries IP65 protection, providing dust and washdown resistance. Combined with an engineered PPA body and nitrile seals, it delivers durable performance in demanding environments.

It offers up to 100 million actuations, reducing maintenance and replacement costs. The high-density island design, integrated fittings, and compact footprint lower total cost of ownership in high-cycle applications like packaging and pick-and-place.

You can access the Datasheet, Brochure, and Installation Guide from Norgren’s download pages: Datasheet (PDF) at en_5_1_300_VM15.pdf, Brochure (PDF) at z9580BR_Valve_Island_Brochure_EN_LR.pdf, and Installation Guide (PDF) VM10 Installation Sheet.