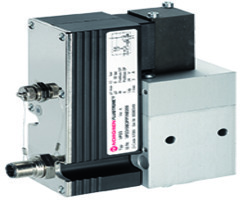

Norgren VP2302BD461MB201 Proportional Valve - IP65

Part Number: VP2302BD461MB201

Quick Summary

Norgren VP2302BD461MB201 is an all-digital proportional valve for precise compressed air pressure control in automation lines across packaging, automation, and process industries. Many engineers struggle with tuning stability and external pressure fluctuations that disrupt performance, cause pressure spikes, or waste compressed air. CE certification and IP65 protection ensure compliant operation in harsh environments, while optional serial interfacing with VP-Tool and fieldbus actuation streamline integration. These capabilities translate into faster commissioning, lower life-cycle costs, and reliable performance under variable demand, supporting manufacturers in automotive, packaging, and pharma processes. Its digital control electronics reduce calibration time while maintaining repeatable responses across temperature and supply variations.

Product Information

Extended Description

VP2302BD461MB201 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

7 ... 17 bar, 102 ... 247 psi

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Range

VP23

Brand

IMI Norgren

All-digital control electronics enable precise, repeatable proportional pressure control with rapid response to demand changes. This translates to tighter tolerances in pneumatic actuation and minimized overshoot, reducing cycle times and waste in high-speed packaging and assembly lines. In practice, you gain steadier valve performance across varying supply quality and ambient temperature, making setup simpler and more robust across multiple machines in a line. The valve is designed for compressed air, with a working range of 7 to 17 bar (102 to 247 psi) and an operating temperature from -5 to 50 °C (23 to 122 °F). These specs support reliable control in rugged factory environments while minimizing leakage and wear. Seals made from nitrile rubber resist common lubricants and provide long service life even in mixed media lines. CE certification and IP65 protection ensure safe operation and compliance in dusty or wet production areas, enabling outdoor installations in some cases. The valve is free of lacquer-affecting substances, contributing to cleanliness in food, pharmaceutical, and electronics manufacturing. This combination reduces regulatory risk and supports maintenance programs by providing predictable performance with minimal environmental impact. Optional fieldbus actuation and serial interfacing with VP-Tool support seamless integration into modern control architectures and digital workflows. The VP23 family is designed for straightforward installation on standard manifolds with compatible pressure ranges, accelerating commissioning and reducing start-up time. Engineers benefit from a proven solution that aligns with lean manufacturing goals, lowers energy usage, and improves process stability across the production line. In practice, the VP2302BD461MB201 supports longer maintenance intervals and lower total cost of ownership due to its durable nitrile seals and sealed electronics, which resist contamination and environmental stress. Customers report faster diagnostics with the VP-Tool interface and quicker spare-part replacement due to standardized VP23 components. The modular design facilitates upgrading to fieldbus control or external pressure management without replacing the entire system, delivering measurable ROI through reduced downtime and improved product quality.

Get a Quick Quote for a Norgren VP2302BD461MB201

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2302BD461MB201?

Enquire Now

FAQs

The VP2302BD461MB201 supports optional fieldbus actuation and serial interfacing with VP-Tool. This enables direct digital control from common automation networks and simplifies calibration. When used with VP-Tool, technicians can set-point, monitor pressure, and tune response without invasive hardware changes. Fieldbus compatibility reduces wiring complexity and speeds commissioning.

The valve is designed for compressed air, with a working range of 7 to 17 bar (102 to 247 psi) and an operating temperature from -5 to 50 °C (23 to 122 °F). Seals are nitrile rubber, offering good resistance to common lubricants and longer service life in mixed-media lines. It carries IP65 protection for dust and water ingress and CE certification for compliance.

IP65 provides dust-tight protection and water spray resistance, enabling reliable operation in harsh factory environments and some outdoor installations. CE certification confirms compliance with essential health, safety, and environmental requirements for European markets. Together, they reduce regulatory risk, simplify audits, and support safer, longer-lasting installations without bespoke protections.

Ideal for automotive, packaging, and pharmaceutical automation, the VP2302BD461MB201 delivers ROI through tighter process control, reduced energy consumption, and lower waste from improved actuation stability. Its digital interfaces shorten commissioning time, while IP65 and nitrile-sealed reliability minimize maintenance and unexpected downtime on high-speed production lines.

Follow VP23 family guidelines for installation on standard manifolds and ensure fieldbus or VP-Tool interfaces are configured to the control system. Regularly verify pressure setpoints, monitor valve response times, and replace nitrile seals as part of scheduled maintenance. The modular VP23 design supports field upgrades, allowing you to add fieldbus control or external pressure management without full system replacement.