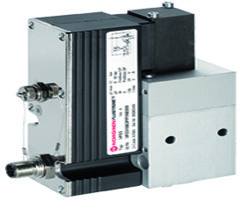

Norgren VP2302BD761MB200 Proportional pressure control valve - IP65 CE

Part Number: VP2302BD761MB200

Quick Summary

Norgren VP2302BD761MB200 proportional pressure control valve provides precise pneumatic regulation for automated systems. Engineers often wrestle with drift, slow response, and integration hurdles when regulating compressed air. This valve supports CE conformity and an IP65 rugged rating, with optional fieldbus actuation or VP-Tool serial interfacing to streamline commissioning. The VP23 family offers compact, reliable control for demanding applications, enabling consistent performance in automation, packaging, and manufacturing environments. By combining all-digital electronics with flexible control options, it delivers measurable business value through improved process stability and reduced downtime.

Product Information

Extended Description

VP2302BD761MB200 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

0 ... 2 bar, 0 ... 29 psi

Port Size

ND8

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

113.3 mm

Dimensions - Length

136 mm

Dimensions - Width

55 mm

Weight

1.1 kg

Country of Origin

Czechia

Range

VP23

Brand

IMI Norgren

Feature: All-digital control electronics provide precise, repeatable pressure output. Business Impact: Reduces drift and improves regulation accuracy, lowering scrap and rework. Application: Fine pneumatic control on high-speed packaging lines. Feature: External pressure control upon request increases system adaptability. Business Impact: Allows tailoring to multi-point networks without extra hardware, cutting assembly time. Application: Custom automation cells requiring remote sensing. Feature: Optional serial interfacing with VP-Tool simplifies configuration. Business Impact: Shortens commissioning, lowers engineering effort, accelerates deployment. Application: OEM line start-up and retrofit projects. Feature: Optional fieldbus actuation enables networked control and monitoring. Business Impact: Supports Industry 4.0 data visibility and remote diagnostics, reducing maintenance visits. Application: Robotic cells and automated conveyors. Feature: IP65, CE certification and nitrile seals withstand harsh environments. Business Impact: Ensures compliance and durability in wet/industrial facilities, reducing spare part variety. Application: Automotive, food & beverage, and process automation. Feature: Compact ND8 port and lean footprint save panel space and simplify integration. Business Impact: Enables easier installation in tight enclosures and retrofit projects. Application: OEM panel builds and compact automation cabinets. Feature: VP23 range compatibility and Czech manufacturing quality. Business Impact: Trusted supply with consistent performance and long-term availability. Application: Global manufacturing environments requiring robust pneumatic control.

Get a Quick Quote for a Norgren VP2302BD761MB200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2302BD761MB200?

Enquire Now

FAQs

Plan for a clean, dry compressed-air supply and proper mounting near the control logic. Ensure IP65-rated enclosure or protection where wiring and connectors are exposed. Use the VP-Tool interface if needed for configuration and verify electrical wiring follows the device’s documentation. The ND8 port size supports reliable, compact piping without added adapters.

Key specs include a 0 to 2 bar operating range, -5 to 50 °C operating temperature, and all-digital control electronics that minimize drift. The nitrile seals provide compatibility with common compressed-air systems, while IP65 protects against dust and water ingress. Optional external pressure control and fieldbus interfaces further optimize precision in dynamic applications.

Yes. The module carries an IP65 rating and CE certification, indicating suitability for harsh environments. Its nitrile seals and robust construction are designed for reliable operation in damp or humid facilities, reducing maintenance needs and enhancing lifecycle performance in industrial automation settings.

The valve supports optional serial interfacing with VP-Tool for straightforward configuration and commissioning. It also offers optional actuation via fieldbus, enabling networked control and remote monitoring. This makes integration into modern automation architectures smoother, especially when deploying within the VP23 range and Profibus-compatible environments.

Maintenance benefits arise from IP65 protection, CE compliance, and nitrile sealing, which reduce leakage risks and part replacements. The all-digital control electronics cut calibration needs, while fieldbus and VP-Tool options shorten setup time. Overall, customers can expect lower downtime, improved process stability, and faster payback in automated production lines.