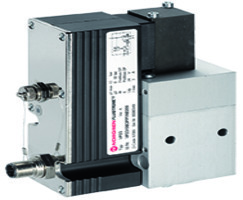

Norgren VP2302BE461MB200 Proportional Valve - IP65

Part Number: VP2302BE461MB200

Quick Summary

VP2302BE461MB200 is a proportional pressure control valve for automated pneumatic systems. Engineers often battle pressure drift and slow response under variable loads, which bottlenecks production lines. This unit uses all-digital electronics and IP65-rated protection, delivering fast, repeatable pressure control in harsh environments. It is CE certified, with options for external pressure control on request and serial interfacing via the VP-Tool program, plus actuation through fieldbus networks. These capabilities reduce commissioning time and improve integration with PLCs and modern automation platforms. By aligning valve performance with upstream supply and downstream actuators, you gain tighter process control, lower energy consumption, and longer equipment uptime in demanding industrial applications. Compressed-air systems benefit from predictable, repeatable results.

Product Information

Extended Description

VP2302BE461MB200 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

0 ... 2 bar, 0 ... 29 psi

Port Size

ND16

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

132.6 mm

Dimensions - Length

166.5 mm

Dimensions - Width

70 mm

Weight

1.7 kg

Country of Origin

Czechia

Range

VP23

Brand

IMI Norgren

All-digital control electronics deliver precise, repeatable pressure output, minimizing drift in high-demand cycles and enabling tighter tolerances in automation lines. This translates to improved cycle times, reduced scrap, and more consistent actuator performance in packed manufacturing environments. External pressure control on request offers flexible system architecture to accommodate varying tooling and process steps, preventing over-sizing and enabling a leaner overall pneumatic design. Serial interfacing with VP-Tool simplifies setup and diagnostics, reducing commissioning time and enabling parameter tuning from engineering workstations. Fieldbus actuation opens networked control with PLCs and industrial networks, cutting wiring complexity and improving real-time diagnostics. With IP65 protection, CE certification, nitrile rubber seals, and ND16 porting, the valve is ready for rugged environments, washdown readiness, and reliable long-term operation. The compact form factor, 132.6 mm height, 166.5 mm length, 70 mm width, and 1.7 kg weight facilitate straightforward installation alongside standard components in VP23-series systems. The design also minimizes lacquer-related contamination, supporting clean-process applications and consistent air quality within critical automation tasks.

Get a Quick Quote for a Norgren VP2302BE461MB200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2302BE461MB200?

Enquire Now

FAQs

Yes. VP2302BE461MB200 uses standard ND16 port sizing, making it compatible with common pneumatic fittings and actuation hardware. Mounting is straightforward on typical manifolds, and the compact footprint supports tight spaces in automation cells.

The valve supports an operating pressure range of 0 to 2 bar and operates from -5 to 50 °C, enabling use across most factory environments while maintaining stable proportional control.

Yes. The device is CE certified and IP65 rated for protection against dust and water ingress. Optional serial interfacing via VP-Tool and fieldbus actuation are available to simplify integration with PLCs and automation networks.

The all-digital control electronics reduce pressure drift, improving process stability and reducing scrap. Fieldbus and VP-Tool compatibility speed commissioning and diagnostics, lowering maintenance time and total cost of ownership in automated lines.

External pressure control allows tailoring the valve to specific process requirements, while fieldbus actuation enables networked control, diagnostics, and remote tuning. Together, they enable scalable, easier-to-maintain pneumatic systems with faster response and tighter process control.