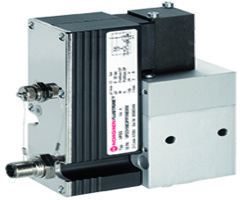

Norgren VP2302BE761MB200 Proportional Valve - IP65

Part Number: VP2302BE761MB200

Quick Summary

VP2302BE761MB200 is a proportional pressure control valve designed to regulate pneumatic pressure with high precision in automated production lines. In practice, fluctuating line conditions and drift can degrade product quality and waste energy; this valve helps mitigate those issues through digital control. With CE certification and IP65 protection, it is built for harsh factory environments while maintaining accurate performance. The device also integrates with VP23 tooling and fieldbus actuation, enabling scalable automation and easier maintenance, reducing total cost of ownership and maximizing line uptime.

Product Information

Extended Description

VP2302BE761MB200 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

0 ... 2 bar, 0 ... 29 psi

Port Size

ND16

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

132.6 mm

Dimensions - Length

166.5 mm

Dimensions - Width

70 mm

Weight

1.7 kg

Country of Origin

Czechia

Range

VP23

Brand

IMI Norgren

All-digital control electronics deliver precise, repeatable pressure modulation, reducing overshoot and stabilizing pneumatic actuation in demanding lines. Business impact: improved process stability, lower defect rates, and reduced energy consumption during valve operation. Application: packaging, robotics, and general automation where tight pressure control is required. External pressure control on request allows tighter regulation for specialized processes, improving quality and consistency across batches. VP-Tool serial interfacing option simplifies calibration and traceability, saving setup time and ensuring repeatable performance in multi-vendor environments. Fieldbus actuation support enables seamless integration with existing control architectures, decreasing integration risk and enabling centralized monitoring. The ND16 port size and nitrile seals balance reliability with compatibility in standard automation components, while the IP65 rating and CE certification provide necessary protection and compliance in industrial settings.

Get a Quick Quote for a Norgren VP2302BE761MB200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2302BE761MB200?

Enquire Now

FAQs

To install VP2302BE761MB200, connect the ND16 pneumatic fittings securely to the valve ports and ensure clean, dry compressed air supply within 0–2 bar. Use proper mounting hardware to minimize vibration, align the valve to avoid stress on the body, and seal all connections with nitrile seals. Verify IP65 enclosure protection by sealing any access points, and perform a functional test with standard control signals to confirm correct modulation and response times.

The VP2302BE761MB200 supports an operating pressure range from 0 to 2 bar (0 to 29 psi) and an operating temperature range of -5 to 50 °C (23 to 122 °F). This makes it suitable for typical factory air systems and environments with moderate temperature variation, while maintaining stable proportional control across the specified range.

Yes. The valve carries CE compliance for European safety and performance standards and is IP65 rated, providing robust protection against dust and water ingress. These certifications support safe operation in demanding industrial environments, enabling reliable performance in automated lines and assemblies without additional enclosure requirements.

Absolutely. The VP2302BE761MB200 offers optional serial interfacing with the VP-Tool program for calibration, monitoring, and traceability. It also supports fieldbus actuation as an option, enabling seamless integration with existing PLCs and control networks. This reduces integration risk and improves sector-ready interoperability across facilities.

Maintenance is simplified by the valve’s all-digital electronics and robust nitrile seals, which resist common contaminants in compressed air systems. The extended stability reduces waste and product variance, improving yield and lowering energy use due to precise modulation. Over time, these benefits translate into measurable ROI through reduced downtime, lower scrap rates, and easier calibration across lines.